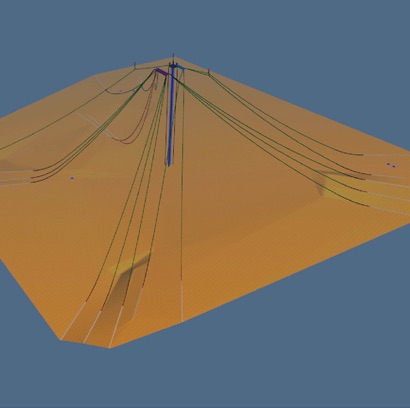

AMOG's expertise and understanding of the dynamic behaviour of mooring systems enables us to analyse and predict the impact of wear and fatigue on assets, and develop a management plan to maximise availability.

We also aim to reduce inspection time, with a consistent focus that targets critical areas, developing high quality, targeted inspection campaign plans that maximise the efficiency of the inspections by tailoring efforts to high risk areas. This eliminated the 'hit and miss' of many inspections, significantly reducing downtime and wasted inspection time and budget.

The Lifecycle Management Process

With our strength in understanding the dynamic behaviour of mooring systems, umbilicals, risers, and jackets, AMOG is able to assist companies with the evaluation and analysis to ascertain which assets are at risk, the magnitude of this risk, and what the risk will be, going forward.

Starting with an understanding of the current status of the asset, AMOG provides a targeted inspection regime, detailing the necessary level of inspection along with work packages that are fine-tined to the specific requirements of the individual asset. These provide an effective and production inspection regime that has the potential to save both time and money, whilst effectively managing risk.

Life Extension

Developing effective management strategies for extending an asset's life generates significant savings. AMOG specialises in implementing these strategies at two key phases of an asset's life:

- Upfront value engineering for Pre-FEED and FEED stages

- Mooring design for inherent reliability and life capability

- RAM

- Operational life extension engineering

- Asset-based RBI planning

- Anomoly assessment

- Re-lifeing and life extension

- Developing asset-based management strategies