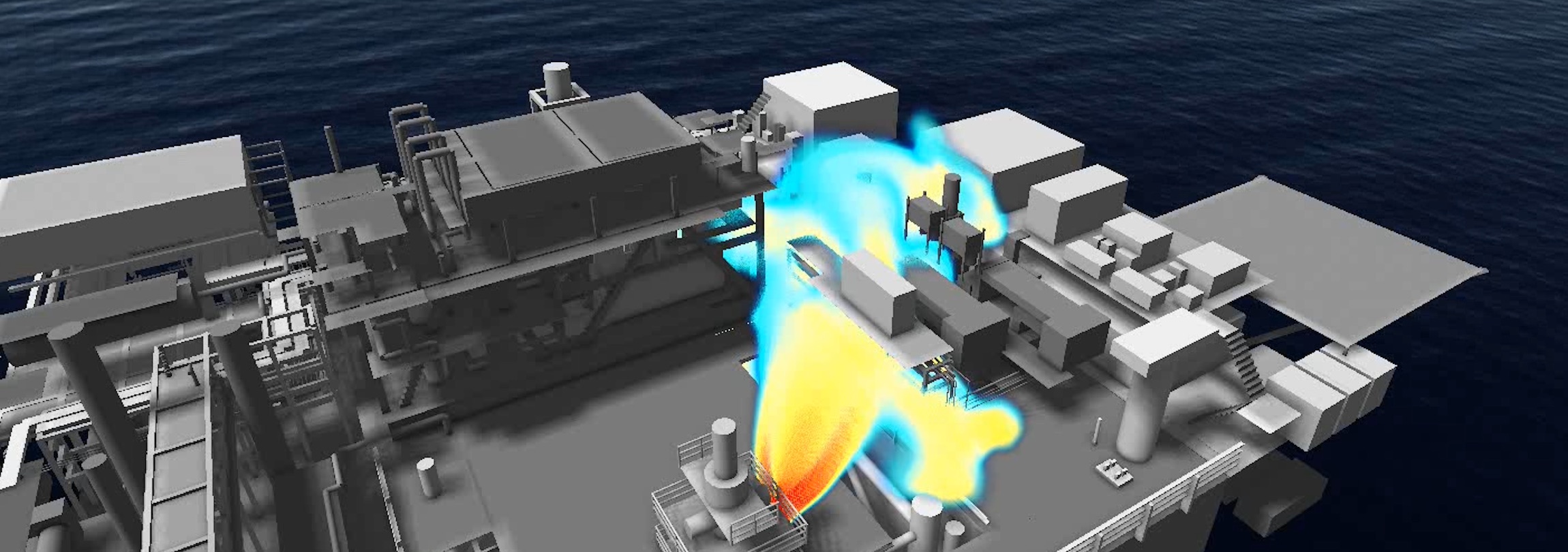

At times, higher fidelity prediction modelling of risks associated with the handling of hazardous chemicals or major accident events is required, and the technique employed is known as Quantitative Risk Assessment (QRA).

QRA provides a basis for decision-making in the design and operation of the plant, and may also be required to show legislative compliance. The analysis does this through an improved understanding of:

- The consequences of hazardous events

- Quantified onsite and offsite risks to personnel safety and environmental impact from hazardous events

- Quantified societal risks

- Legislative compliance assessments

- Potential for impaired critical systems (such as safety systems, muster points and egress routes)

- Potential for escalation of events to adjacent inventories or sensitive infrastructure

- Guidance on planned, present and future facilities (inclding the suitability location and construction of occupied buildings)

- Fire Safety Studies

- Emergency response and evacuation planning requirements and procedures

AMOG has a long history of providing QRA services across the globe in a wide range of industries, including offshore oil and gas, marine and naval vessels, onshore petro-chemical facilities, munitions and explosives, underground mining and tunnels.

AMOG’s highly trained professional engineers have the skills, experience and tools to analyse a wide range of hazardous chemicals and events. This includes correlations and formulae, empirical based tools (such as DNV Phast/Safeti), analytical tools (such as FLACS, FDS, FireEx), advanced full physics solvers (such as Star-CCM+, CFX, Fluent, LS Dyna) and physical model testing.