HOME > INDUSTRIES > ONSHORE PROCESSING & MHFs

ONSHORE PROCESSING & MHFs

Fatalities, injuries, property damage and business interruption can cause a substantial drop in share price and loss of market share for a company. Disruption of normal business activity can cause a temporary loss of corporate direction by diverting senior management’s attention from running the business to overseeing damage control. Additionally, company officers may be subject to personal liability and even criminal charges.

Process safety is a blend of engineering and general management. It focuses on preventing catastrophic accidents and near hits associated with a loss of containment of energy or hazardous chemicals. These engineering and general management skills exceed those required for managing workplace safety, as they impact people, property and the environment.

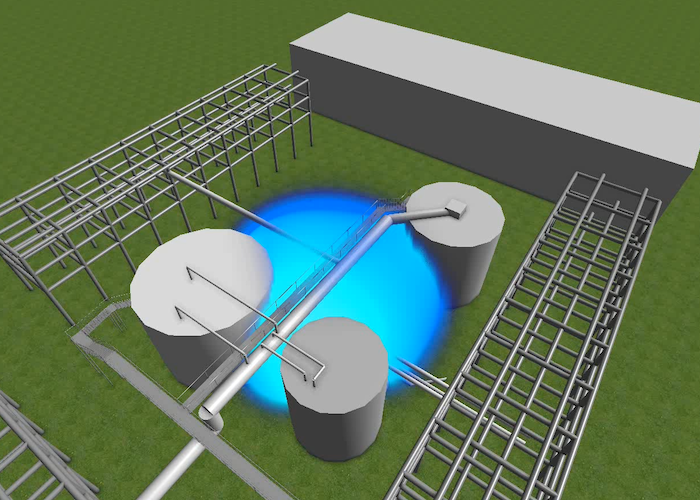

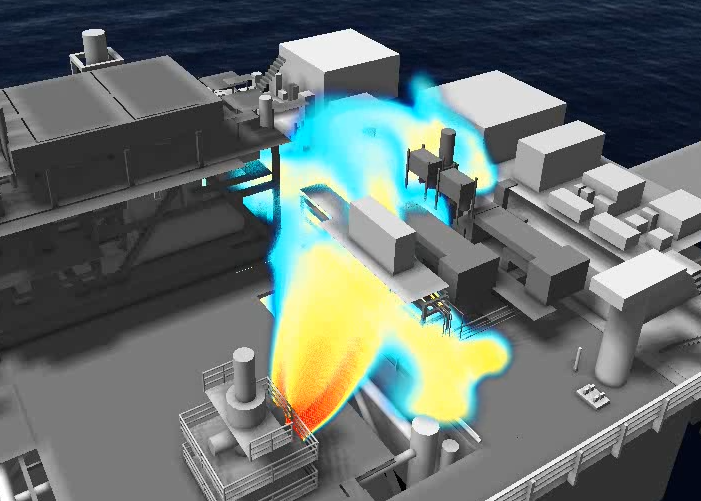

AMOG’s highly trained professional engineers have the skills, experience and tools to analyse a wide range of hazardous chemicals and events. This includes correlations and formulae, empirical based tools (such as DNV Phast/Safeti), analytical tools (such as FLACS, FDS, FireEx), advanced full physics solvers (such as Star-CCM+, CFX, Fluent, LS Dyna) and physical model testing.

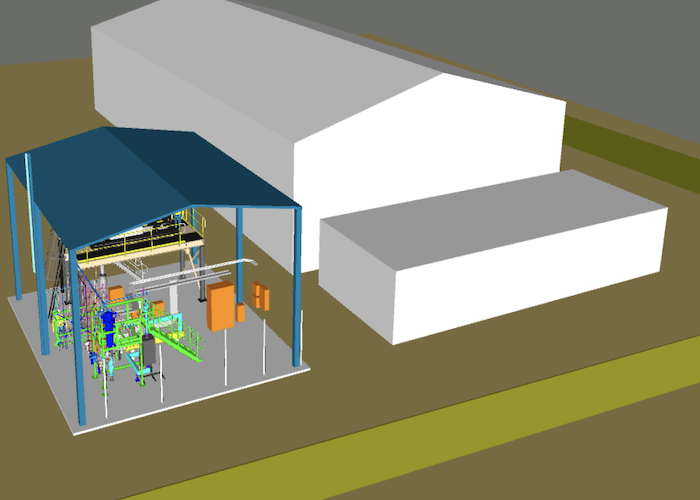

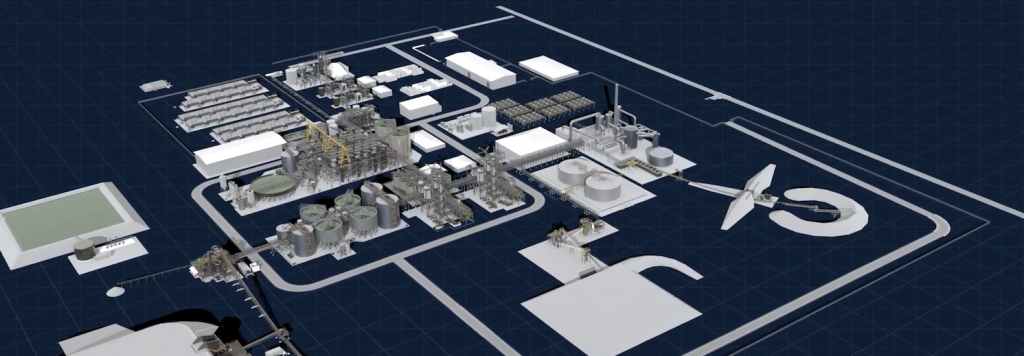

- Conceptual design of process facilities

- Process system simulation (HYSYS, PIPESYS)

- Production chemistry

- HAZID/HAZOP of process systems (including rare earth & radiation safety)

- Troubleshooting process plant design and commissioning

- Chemical dosing and corrosion management

- Advanced process modelling, including:

- Dynamic modelling (transients, cold startup, blowdown operations & water hammer)

- Conjugate CFD thermal modelling

- Detailed erosion modelling

- Multi-phase CFD modelling

- Coupled process/mechanical integrity assessment (FIV, low temp)

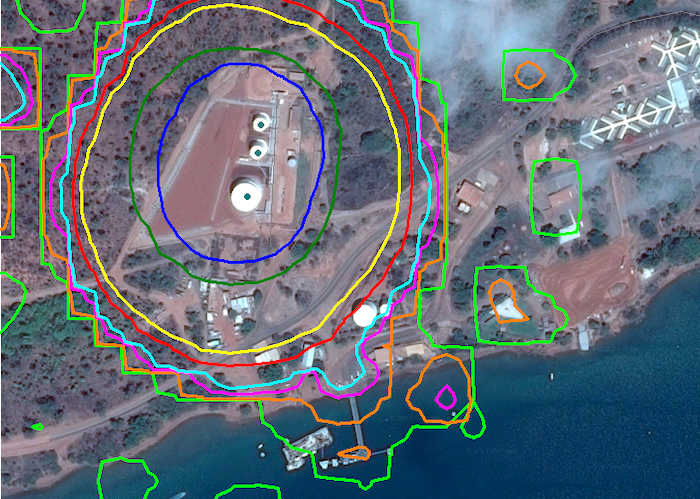

AMOG has specialist skills and experience with the Work Health and Safety (WHS) regulations governing Major Hazard Facilities (MHFs). We provide all aspects of MHF safety case development, safety and risk assessments,consequence modelling, and independent reviews and audits. AMOG has provided expert advice and safety engineering services working on MHF sites for over five years, with a broad range of experience. We have well trained safety specialists with detailed knowledge of State specific and Commonwealth regulatory requirements and approval processes and are known to regulators as qualified MHF assessors.

In addition to knowledge of legislation and well developed processes for MHF license applications and renewals, AMOG has proven capability in major accident event consequence modeling and Qualitative Risk Assessments (QRAs). AMOG is well placed to deliver:

- Initial scoping studies or gap analysis for regulatory compliance

- Assistance in the development/update of the Safety Case / Report and outline plans

- Preparation of documents for supply to regulators

- Advice in obtaining MHF licences

- Ongoing independent review and auditing

- Training

- Hazard identification workshops

- Quantitative / Qualitative risk assessments

- Control measure evaluation and development of performance indicators

- Development of integrated Safety Management Systems

- Major accident event consequence modeling for QRAs

AMOG is in on the COMCARE Panel of Approved Assessors for Safety Report for Major Hazard Facilities. The Commonwealth regulator has also recognized AMOG’s expertise through our continued appointment and utilization on the Comcare Panel for Provision of Specialised Technical Services Related to Risk Management of High-Risk Industries. In fulfilling these roles, AMOG has been, and still is, intimately involved with Work Health and Safety Act and Regulations 2011 and the associated Codes of Practice.