HOME > INDUSTRIES > MINING

MINING SECTOR

AMOG has a proven track record of providing leading engineering solutions and innovation, offering unique capability in the analysis, design and assessment of facilities, plant and infrastructure for the mining sector. We specialise in smart systems and innovative services to:

- Provide specialist engineering support, structural inspections and third party assurance for aged and new infrastructure design

- Enhance and optimise throughput from machinery and plant

- Minimise disruptions to operations and operating costs

- Optimise maintenance, spares inventory and improve reliability

- Increase design life, capacity and optimise refurbishment strategies

- Assess and manage compliance of health, safety and environmental impacts

We provide engineering services across the supply chain including: mining, processing, refining and transportation (road, rail and sea) infrastructure. Our clients are global and include iron ore, coal, copper, gold, nickel, aluminium, diamonds and manganese. To support our clients we have offices located in Australia, Europe and North America, and can undertake:

- Asset Management: technical services, innovative products and governance for full life-cycle asset management

- Structural Assessment and Investigation: specialist knowledge, FEA, design and inspection services and third party assessment

- Production Enhancement and Optimisation: balancing optimisation and increases in throughput with risk and asset management

- Health and Safety Engineering: design support, compliance assessment and corporate governance to meet legislative requirements

Visit our list of project experience for more information.

AMOG has a proven track record of providing engineering inspection for minesite structural assets. Our experience in structural engineering, maintenance optimisation and automated integrity management systems mean AMOG is uniquely positioned to help identify structural deficiencies and integrity issues relating to minesite infrastructure and equipment.

To ensure integrity is maintained and at-risk items can be addressed for infrastructure and equipment, AMOG can undertake:

- Civil Inspections

- Structural Inspections

- Mechanical Inspections

- Marine Inspections

- Dangerous Goods Inspections

- Fatigue Assessment

- Life Extension

- Regulatory Compliance

- Condition Monitoring

- Dangerous Goods Inspections

- Equipment

- Stacker Conveyers

- Ship Loaders

- Drill Rig Towers

- Reclaimers

- Stock Bridges

- Conveyers

- Drag Lines

- Plant and Facelift

- Bulk Handling Equipment

- Cranes

- Bridge and Gantry Cranes

- Mobile Cranes

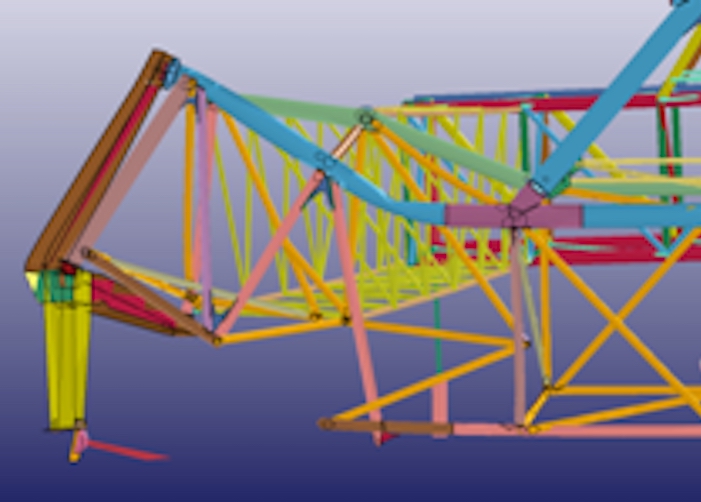

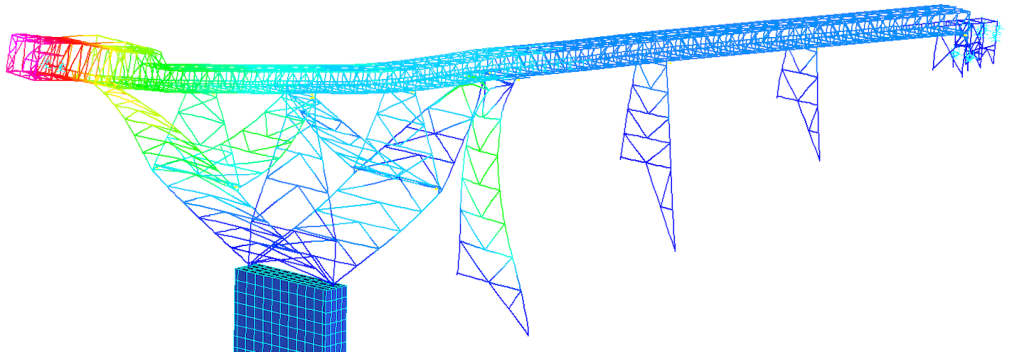

- Boat Cranes

AMOG can assist mining equipment designers and operators with the management of machine integrity through all stages of the plant life cycle. Through application of advanced structural and dynamic analysis techniques, the reliability and production of equipment can be improved, replacement intervals for machine components extended, and the remaining life in aged equipment assessed and extended.

AMOG offers our clients the following services for the management of mining equipment integrity:

- Linear and Nonlinear Finite Element Analysis (FEA)

- Load Duty Assessment

- Load Case and Spectrum Definition

- Fatigue Analysis

- Life Extension Studies

- Pushover Analysis

- Joint Cracking / Fracture Analysis

- Strength and Fatigue Assessment to AS4324 and Other Codes

- Failure Investigation / Root Cause Analysis

- Steel Wire Rope Life Optimisation

- Risk evaluation and assessments

- Plant Integrity Reviews (PIRs)

- AS4324 Appendix K Structural Design Audits

- Failure Investigation / Root Cause Analysis

- Computer Based Training of Machine Operators

- Instrumentation of Machine Dynamics

AMOG can assist designers, manufacturers, operators and regulators in the mining sector. We have extensive experience with structural design and analysis, design verification and audits, inspections (including Risk Based Inspection (RBI) techniques), integrity management, system safety engineering, and experience with expert witness engagements for a variety of legal cases involving complex forensic engineering and failure investigations.

AMOG has experience in the mining sector management of plant, equipment, and support structure integrity through all stages of the plant life cycle. We undertake advanced Structural Engineering analysis of assets and equipment ranging from bulk material handling machines, conveyors, tunnels, tanks, silos, pipelines and support structures for any plant or equipment equipment. Using state of the art analytical packages, AMOG can design and assess complex structures and components requiring non-lineal solutions. Our services in this area include:

- Large displacement and staged Finite Element Analysis (FEA) with linear and non linear material and geometry

- Fracture, Fatigue, and Joint Cracking Analysis to AS 4100, BS 7608, EN 1993-1-9, DNVGL- PR-0001 and more

- Assessment of existing Structures to AS ISO 13822, including civil structures and foundations > Reliability, Strength and Robustness to AS 1170, AS 5104, ISO 2394, AS 4324, AS 4100, AS 3990, AS 3600 and more

- Structural Design Audits of Mobile equipment for bulk materials to AS4324 Appendix K

- Pushover, Criticality and Stability Analysis

- Load Duty Assessments

- Risk evaluation and assessments

- Plant Integrity Reviews (PIRs)

- Failure Investigation / Root Cause Analysis

Maximise Utilisation, Minimise Downtime, Reduce Costs, and Improve Safety.

AMOG has a proven track record of providing engineering solutions for fixed plant/machinery and rail mounted machines. Our experience in structural engineering, maintenance optimisation and automated integrity management systems mean AMOG is uniquely positioned to help maximise utilisation, minimise downtime, reduce costs, and focus on safety.

AMOG specialises in maintenance optimisation for mining machinery and equipment with the application of Risk Based Inspection (RBI) techniques. Through the understanding of key degradation mechanisms and credible failure modes, AMOG is able to determine how machine history, control settings and operation affect structural integrity. Using RBI to target critical locations on an asset can reduce machine downtime for maintenance by scheduling inspections at intervals based on the individual asset’s health and performance over time. Inspection findings can be used to focus future inspections and extend inspection intervals by providing feedback on uncertainties in fatigue damage and corrosion/wear predictions, thus reducing the cost of inspection programs.

In addition, AMOG can use RBI to identify critical controls for managing machine integrity, improve operation performance of the machine, and investigate life extension of the asset. Our experience with RBI can be applied to existing machinery, used to incorporate learning from current RBI programs, and be tailored to complement existing processes for asset management and functional safety management. This knowledge can also be applied to the procurement of new machines and assets or to identify critical spares and critical skills.

AMOG has RBI experience across a number of different machine types and ages, with significantly different utilisation, different OEMs, and machines designed to different industry codes.

AMOG can support clients in the mining sector by offering the following services:

- FEA based structrual assessments, machine monitoring and detailed inspections

- Procedures and templates for redesigned RMP programs

- Machine utilisation reports based on operationaprofiles (not assumed loads and combinations from AS4324)

- FMECA

- Reliability Centred Maintenance (RCM)

- Reports on detailed utilisation for strength, fatigue and buckling for entire structure (not just 20 worst locations, as per design assessments)

- Definition of legislative obligations for machine inspection

- RBI intervals within codified reliability targets

- Legal and Expert Witness services

Is your plant showing fatigue cracks?

Can your plant withstand more throughput?

How long to your next shutdown?

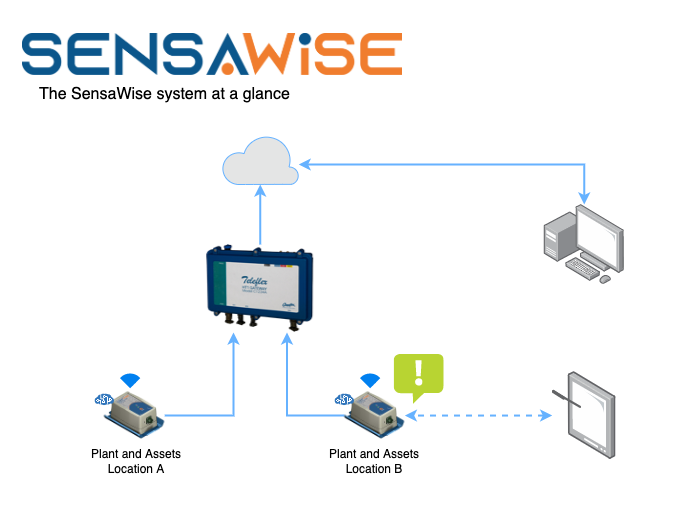

AMOG offers data-driven asset monitoring solutions for the mining sector, aimed at validating equipment and control system design, improving safety, and optimising throughput.

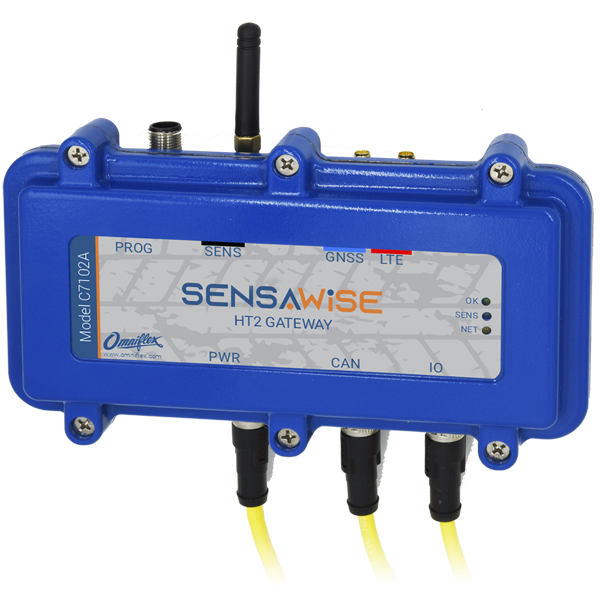

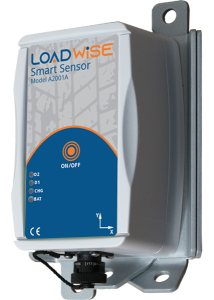

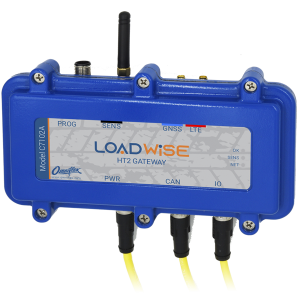

AMOG’s SensaWise solutions bridge the missing link between gathered sensor data and useful operational feedback in a single holistic package. The SensaWise system, which can be installed on existing assets, gathers data which is fed into digital twins of the asset and used to monitor plant and structural response, relative to design, in real time. SensaWise nodes with their edge processing capabilities can identify failures in real-time, monitor and relay data and pro-actively manage alarms and integrate with control systems.

Blasting can yield uneven fragmentation of ore, resulting in large pieces of rock called “oversize”. In most instances in open cut mining, oversize material is excavated and transported to the Run of Mine (ROM) area and processing plant by haul trucks. The oversize material then collects in ROM bins or chutes forming blockages as it is too large to feed into the primary crushers. The oversize material impedes the flow of ore, reduces production rates, and can completely block the inlet to the primary crusher causing a shutdown of the plant whilst the blockage is removed. This causes costly delays in production, damages crushing equipment and introduces safety hazards to maintenance personnel when removing the blockages.

LoadWise is a system designed for data gathering in haul truck applications. The LoadWise system is designed to be scalable such that it can be implemented on a single truck or rolled out across an entire fleet. With the scale of the deployment defined, system components can be retrofitted onto the selected haul truck(s). The system operates in real time to detect and alert when oversized loads are loaded onto the instrumented haul trucks. The outputs from the LoadWise system can assist in improving truck-routing decision-making, which can reduce crusher blockages and optimise crusher throughput.

Though the system’s core functionality is for oversize detection, the system can be extended to perform other functions such as human vibration tolerance monitoring for haul truck operators and road condition monitoring.

Analysis of hazard risk leads to the identification of risk mitigation and safety requirements. This process identifies critical functions (called safety functions or safety related control functions) which must perform with a level of dependability or integrity. This level is known as a Safety Integrity Level (SIL), a Performance Level (PL) or a Category Level (CAT).

A number of international and national functional safety standards exist that define the requirements for allocating and analysing safety levels. AMOG has extensive experience in the application and independent verification and validation of systems against standards such as:

- IEC/AS61508

- IEC/AS61511

- IEC/AS62061

- ISO13849

- AS4024 >

AMOG has been successfully providing independent functional safety services across a number of asset and safety critical environments for more than a decade. With a large team of experts in all areas of functional safety, AMOG delivers leading-edge results in a focussed and responsive manner. AMOG can provide the following services:

- Conducting Hazard Identification and Risk Assessment to determine SIL/PL/CAT requirements

- Determining System and Software SIL Classification

- Identifying Safety Related Control Functions > and Safety Critical Elements

- Developing safety requirements specifications

- Producing independent safety validation plans and commissioning specification

- Independently validating system safety > performance

- Conducting Independent SIL verification (hardware and software)

- Performing Design Assurance Assessment

- Providing Functional Safety Training

- Offering specialist independent advice

AMOG’s extensive experience in functional safety engineering, highly qualified and dedicated team of professional functional safety engineers (Masters qualified, TUV FSE certified) and state-of-the-art software makes AMOG the smart choice for all your functional safety needs.

AMOG offers its clients a highly developed capability in dynamic vibration monitoring of mining structures. This industry-recognised capability is founded upon the combination of experience gained from many years of structural vibration monitoring and analysis, utilising state-of-the-art vibration measurement tools and in-house developed software for vibration analysis.

- Long Term Vibration Monitoring of Dynamically Responsive Structures

- Data Processing, Analysis and Interpretation

- Crack Growth Prediction

- Development of Vibration Mitigation Strategies

- Monitoring and Prediction of Fatigue Damage Accumulation

- Structural Residual Life Assessment