HOME > SERVICES > STRUCTURAL ENGINEERING

STRUCTURAL ENGINEERING

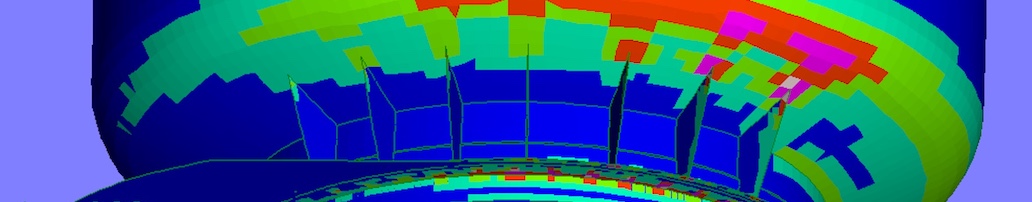

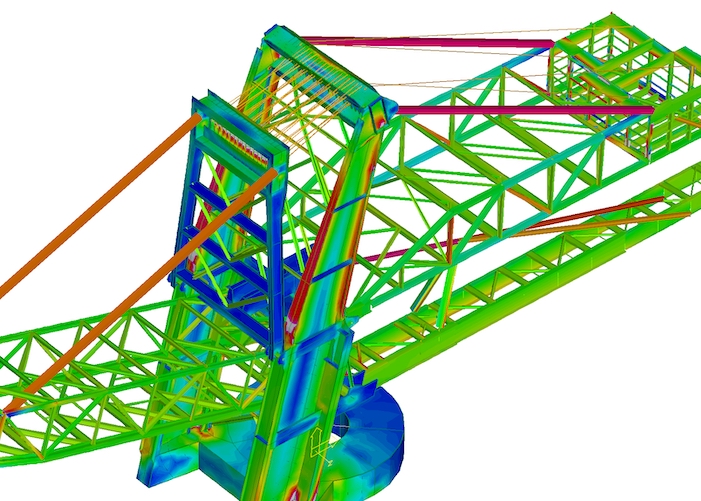

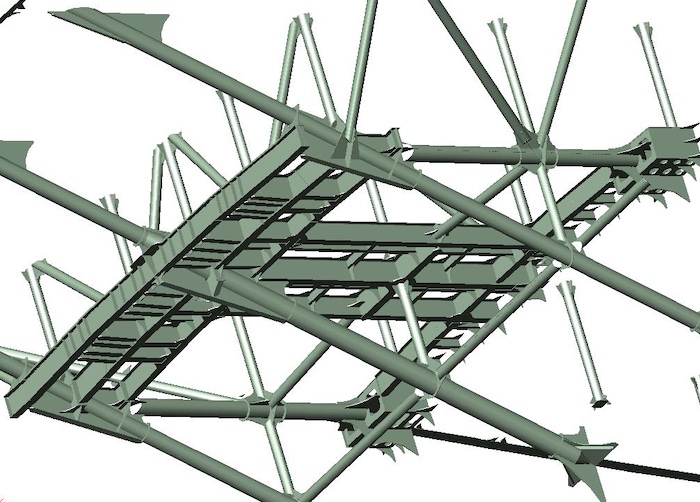

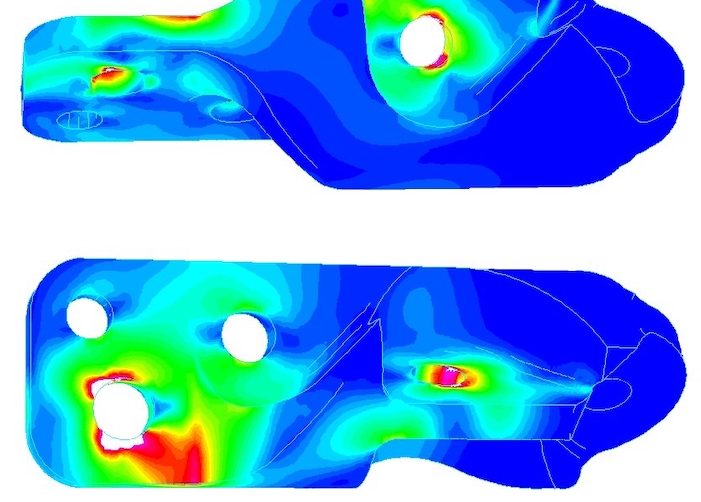

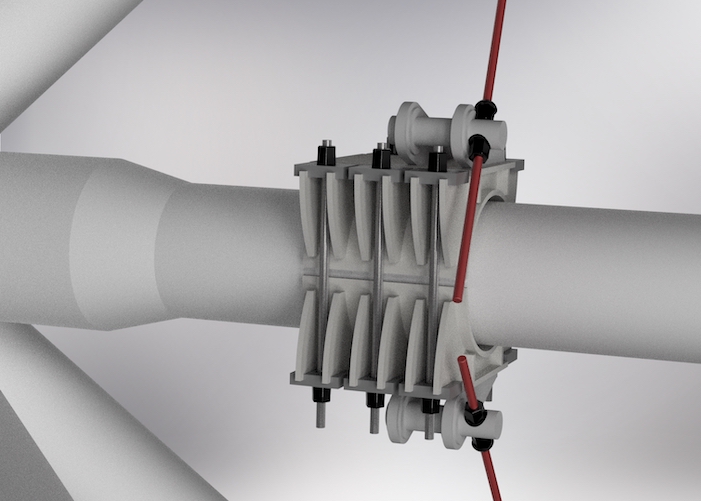

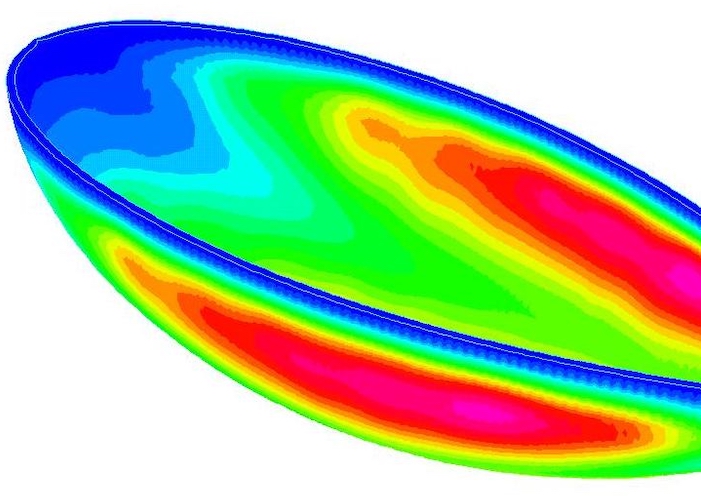

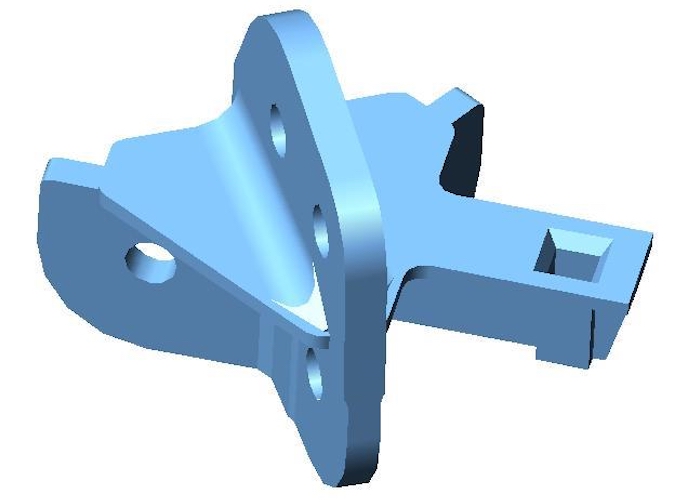

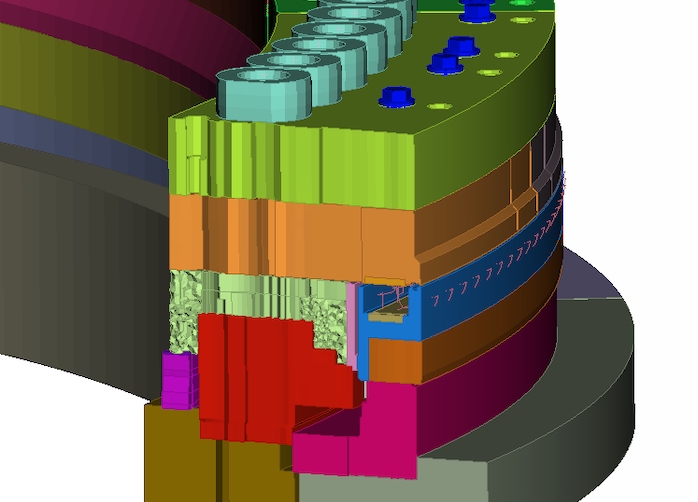

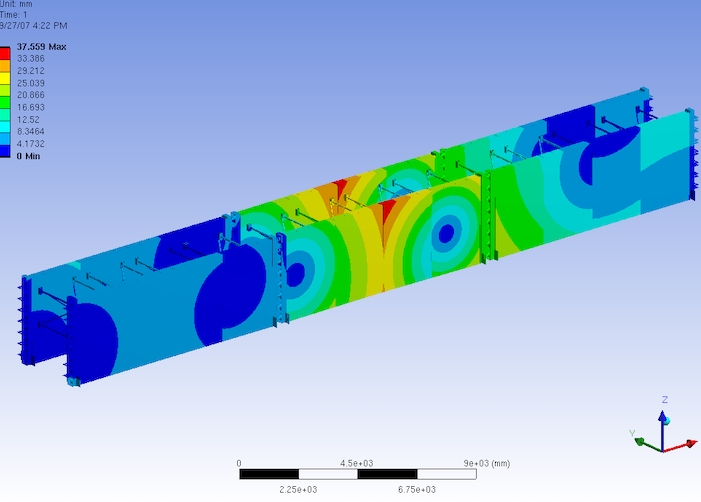

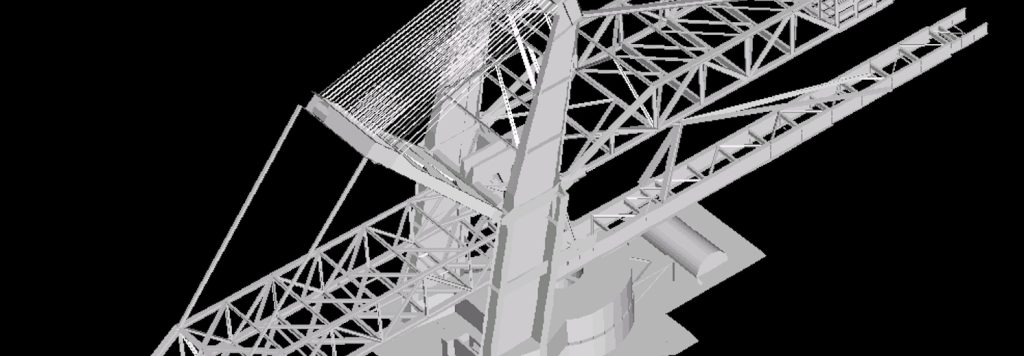

AMOG undertakes advanced engineering analysis and detailed design of marine and land based structures and systems. This industry-recognised capability is founded upon the combination of experience gained from many years of active consulting and leading-edge research with the expert application of advanced numerical techniques and state-of-the-art software-based analytical tools.

AMOG’s capabilities include:

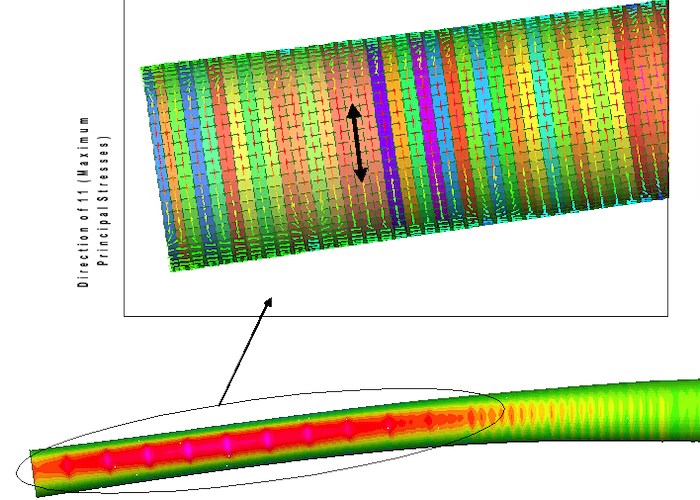

- Implicit and explicit non-linear element analysis techniques

- Post yield and collapse behavior prediction

- Material rupture simulation

- Accounting for non-linear geometric and material strain rate effects

- Multi-component contact interaction and friction

- Blast and collision loading

- Large displacement time domain analysis

- Fatigue and Fracture mechanics

AMOG is able to support clients with the following structural engineering services:

- Design of Offshore and Onshore Structures/Components

- Structural Design Appraisal, Reassessment and Third-Party Audit

- Condition Monitoring and Instrumentation of Structures

- Failure investigation and Forensic Engineering

- Fracture Mechanics Assessments

- Fatigue Assessments, Life Extension and Structural Upgrades

- Impact Assessments

- Blast and Collapse Analysis

- Hydrodynamic Loading Structures

- Structural Assessment of Dynamic Systems

- Fracture Mechanics Assessments

- Design Drafting

AMOG can assist designers, manufacturers, operators and regulators in the mining and offshore sectors. We have extensive experience with structural design and analysis, design verification and audits, inspections (including Risk Based Inspection (RBI) techniques), integrity management, system safety engineering, and experience with expert witness engagements for a variety of legal cases involving complex forensic engineering and failure investigations.

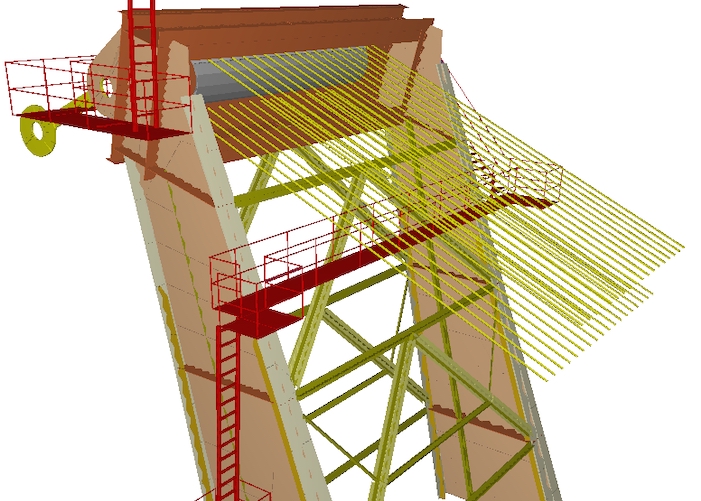

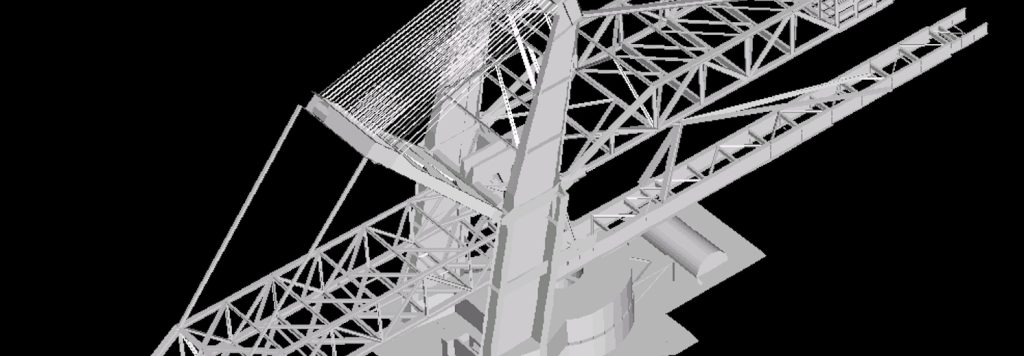

MINING

AMOG has experience in the mining sector management of plant, equipment, and support structure integrity through all stages of the plant life cycle. We undertake advanced Structural Engineering analysis of assets and equipment ranging from bulk material handling machines, conveyors, tunnels, tanks, silos, pipelines and support structures for any plant or equipment equipment. Using state of the art analytical packages, AMOG can design and assess complex structures and components requiring non-lineal solutions. Our services in this area include:

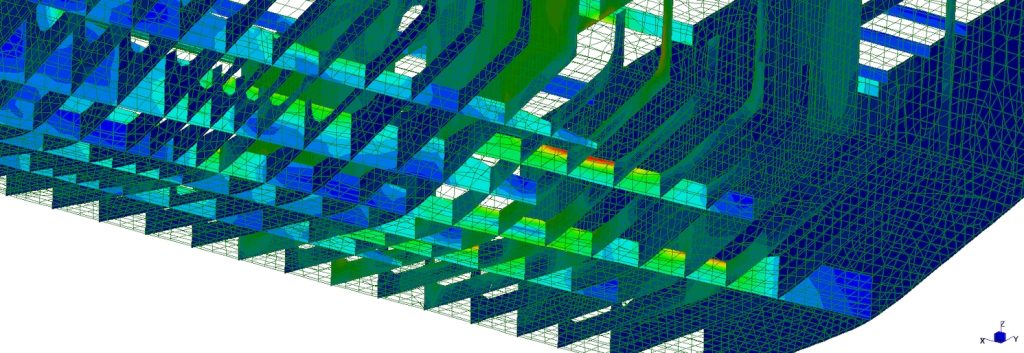

- Large displacement and staged Finite Element Analysis (FEA) with linear and non linear material and geometry

- Fracture, Fatigue, and Joint Cracking Analysis to AS 4100, BS 7608, EN 1993-1-9, DNVGL- PR-0001 and more

- Assessment of existing Structures to AS ISO 13822, including civil structures and foundations > Reliability, Strength and Robustness to AS 1170, AS 5104, ISO 2394, AS 4324, AS 4100, AS 3990, AS 3600 and more

- Structural Design Audits of Mobile equipment for bulk materials to AS4324 Appendix K

- Pushover, Criticality and Stability Analysis

- Load Duty Assessments

- Risk evaluation and assessments

- Plant Integrity Reviews (PIRs)

- Failure Investigation / Root Cause Analysis

OFFSHORE ENERGY

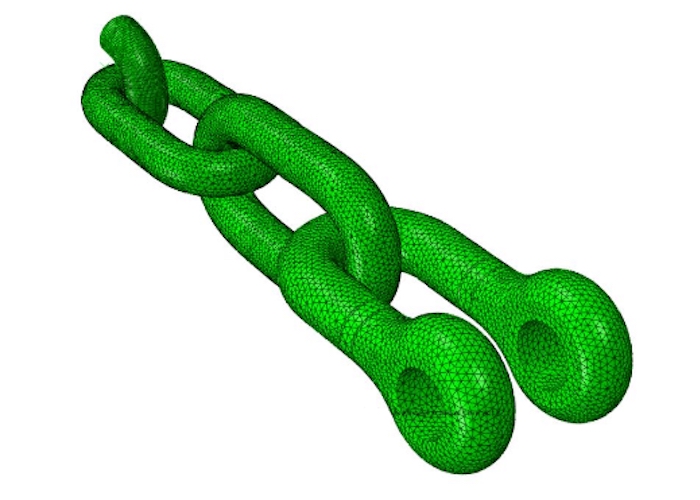

In the offshore oil and gas sector, AMOG as extensive experience and string industry credentials in designing mooring and riser systems for floating production systems, design verification and audits, interpretation of Metocean data, model testing, structural design, hydrodynamics, naval architecture, and system safety engineering, enables AMOG to undertake complex failure investigations. Over the years, AMOG Consulting has been engaged as an expert witness for a variety of engineering legal cases. AMOG can be engaged as an expert witness and undertake investigations relating to:

- Premature Failures from Extreme Events, Fatigue or Mechanical Damage

- Failure of both Offshore and Onshore Structures

- Fluid Loading and Motion Analysis of Fixed, Compliant and Floating Structures

- Hydrodynamics of Multi-Body Systems, including Interaction Effects

- Design and Fatigue Analysis of Offshore Structures and Onshore Building and Structures

- Failure of Mooring Systems, Riser Systems, and Offshore Pipelines

- Failure of Ship Structures:

- Hull Design and Sea Keeping

- Strength and Fatigue Endurance of Ship Structures

- Hydrostatic Stability

- Cargo Securing Systems

- Damage to Ship Hulls and Structures due to Ship Collision

AMOG uses advanced structural analysis capabilities and leading edge materials corrosion knowledge to develop remediation and life extension schemes for degraded or aged steel reinforced concrete structures. This experience extends to the initial inspection and condition assessment of structures, determining rates of corrosion progression, analysis of residual strength, development of cathodic protection schemes, and development of fibre reinforced plastic (FRP) composite repair schemes.

We offer the following services for concrete structures’ life extension and remedial engineering:

- Development of Inspection Schemes for Condition Assessment

- Specification and Management of Diver Inspections for Waterside Structures

- Assessment of Residual Strength of Degraded Structures

- Assessment of Corrosion Damage Accumulation and Residual Life

- Development of Cathodic Protection Schemes for Steel Reinforced Concrete Structures

- Development of FRP Repair Schemes to increase Structural Capacity

- Specification f Long Term Inspection and Condition Monitoring Programs

We offer the following services for metal structures:

- Development of Inspection Schemes for Condition Assessment

- Design, Setup and Operation of Load Monitoring Systems

- Assessment of Residual Strength of Degraded Structures

- Assessment of Corrosion Damage Accumulation and Corrosion in Harsh Environments

- Assessment of Fatigue Life from Operational, Environmental, and Thermal Loads

- Development of Cathodic Protection Schemes for Steel Reinforced Concrete Structures

- Development of Targeted Structural Refurbishment and Inspection Schemes

- Specification of Long Term Inspection and Condition Monitoring Programs

- Development of Risk-based Structural Integrity Management Systems

- Australian Agent for the CrackFirst Fatigue Sensor System

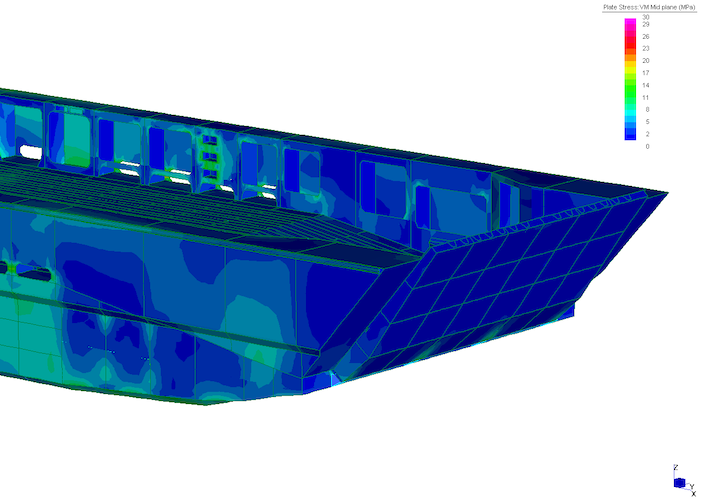

We understand the dynamics and environmental loadings in marine applications to conduct structural assessments of marine assets such as FPSOs and other general ship structures. Such assessments can be used to evaluate the structural integrity of the vessel and to support programs of life extension, optimise maintenance regimes, assess structural risk for extreme operating conditions or develop structural modifications to mitigate existing damage.

This expertise in hydrodynamics, advanced numerical analyses, and model testing, combined with our experience in offshore operations enables us to offer an efficient, accurate and reliable framework for the integrity management of whole subsea systems including mooring, riser, umbilical, hulls, and ancillary equipment.

The benefits of a whole system integrated management philosophy are:

- Reduction in the Cost of Inspection and Maintenance

- Optimisation of System Uptime and Reliability

- Provide Framework for Implementation of Remedial Actions

- Increase Confidence in System Integrity

- AMOG is able to support clients by offering the following services relating to Asset Integrity Management:

- Development of Risk Based Maintenance Plan Inspection and Maintenance Plan

- System Failure Prediction and Assessment

- Identification of Failure Mechanisms

- Fatigue and Residual Life Assessment

- Condition Monitoring, Instrumentation and Inspection

- Development of Emergency Response Plans

- Development of Risk Registers

- Hull Fatigue and life extension assessments

- Assessing both existing and predicted fatigue damage to hull structures

- Based on prior inspection campaigns

- Generating risk-based remediation and inspection guidance reducing expenditure and downtime

- Hull Structural Analysis:

- Using tools such as ABS DLAFOS, SafeHull and advanced Non-linear FEA packages

- Incorporating actual operating experience and data from ullage records, metocean histories and vessel MRUs

- Validating findings against previous inspection results and compliance with relevant design codes

- Assessment of extreme events, repairs and configuration changes:

- Investigation of buckling of frames, propagation of fatigue cracks and component failure

- Predictions of hull locations most susceptible to damage and determination of the extent of damage that may be expected

- Design and specification of remedial repairs, upgrade modifications or operational limits If you require a more detailed capability document and information on our project experience, please email us: info@amog.consulting AMOG Pty Ltd ACN 065 475 818 www.amog.consulting