HOME > PROJECTS > JIPs

Advancing research & development and innovation through collaboration and Joint Industry Projects

At AMOG, we place a strong emphasis on research, which is fundamental to our mission. We have initiated several Joint Industry Projects (JIPs) in collaboration with global organizations, focusing on industry-leading research. Leveraging our expertise in analysis, modelling, and advanced technology, JIPs aim to expand the knowledge base in critical fields, driving innovation and progress.

AMOG JIPs

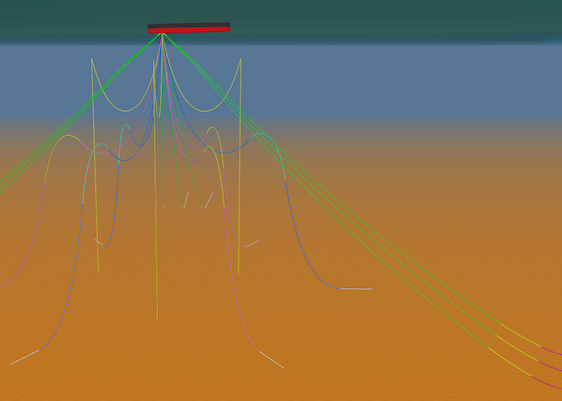

SHEAR7

In 2024, MIT passed the management and control of the SHEAR7 JIP to AMOG. SHEAR7 is the offshore industry’s leading software tool for the prediction of Vortex-Induced Vibration (VIV) with close to twenty years of industry use and continuous development.

AMOG has undertaken research for DeepStar® over numerous years, incl Project 11405 – the development of an industry guideline for the application of risk based asset integrity management practices to permanent mooring systems for floating production facilities. These have formed a basis for the American Petroleum Institute’s (API) Recommended Practice for Mooring Integrity Management, API RP 2MIM.

Learn More

This JIP was established by AMOG in response to an industry need for design guidance for addressing corrosion of chain and wire rope in tropical waters, leading to being able to predict corrosion rates and being provided with insights to avoid unplanned change outs of moorings and mooring failures due to corrosion.

PWC (Preferential Weld Corrosion)

A new JIP looking to resolve uncertainties and improve knowledge of PWC incorporating industry surveys, characterising features, studying driving factors, and providing industry guidance tools. For more information contact Tim Lee or Andrew Kilner at AMOG or Joerik Minnebo at SOFEC Inc.

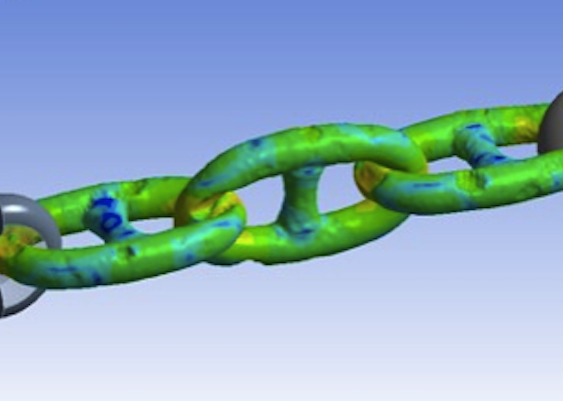

Chain FEARS (Finite

Element Analysis of

Residual Strength)

Following the success of SCORCH, this JIP derived a proven methodology to assess the remaining strength and fatigue life of chain links damaged by wear/corrosion, including industry guidance for performing reliable FEA to assess remaining strength and fatigue endurance, as well as discard criteria.

Chain Wear Joint industry Project

Proposed JIP to develop a more robust methodology for predicting aimed at reducing operational costs through the minimisation of costly unplanned mooring repairs, and increase the level of safety and reliability of mooring systems. For more information, contact Kanishka Jayasinghe at AMOG.

Squall Mooring JIP

Objectives of this proposed JIP focus on identifying the fundamental drivers of squall response for turret moored platforms and tandem offload systems, developing an industry consensus approach to the analysis, and provide industry guidance on design basis data and analyses. For more information, contact AMOG.

WIPMIC (Water Injection Pipe Micro biologically Induced Corrosion)

Aimed at investigating micro-biologically induced corrosion in water injection pipes, focusing on understanding and mitigating its impact on system integrity and reliability, seeking to develop a quantitative predictive model, and design and operational guidelines.

ACARP

AMOG were awarded ACARP funding to investigate extending the life of pendant ropes on coal reclaimers by conducting a study into alternative rope materials

Please contact us for more information on any of these JIPs.