SYSTEMS & SAFETY ENGINEERING

AMOG are leaders in the provision of safety engineering and safety management services to high risk industries both off and onshore alike. We have highly qualified and experienced Functional Safety, Risk and Reliability Engineers who can assist in all aspects of HSE and RCM services. We have significant experience in the development of full offshore safety cases through to specialised QRA activities. In addition, we are experts in onshore Major Hazard Facility (MHF) regulatory compliance and can assist in developing Safety Reports, Safety Management Systems and all other activities associated with MHF licensing processes. We provide advanced analytical services such as CFD and FEA to solve all of your Consequence Modelling requirements and deliver industry respected training courses in Functional Safety Engineering and Management.

- Safety Case Development

- HSE engineering from pre-feasibility through pre-FEED, FEED, detailed design, and installation

- Quantitative Risk Assessment (QRA)

- System Safety Engineering

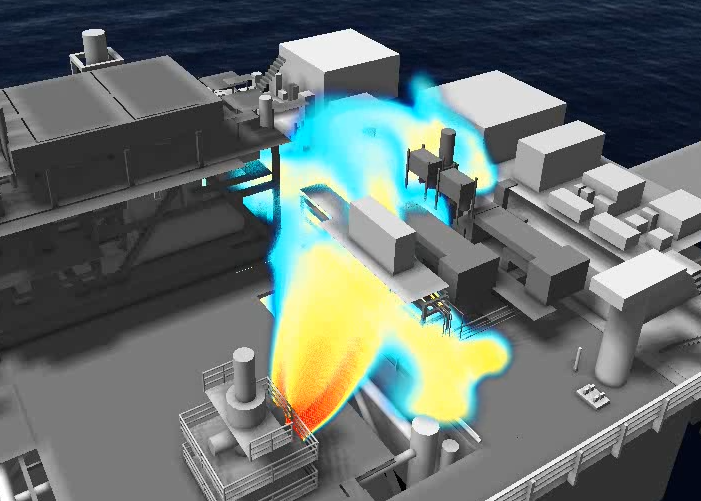

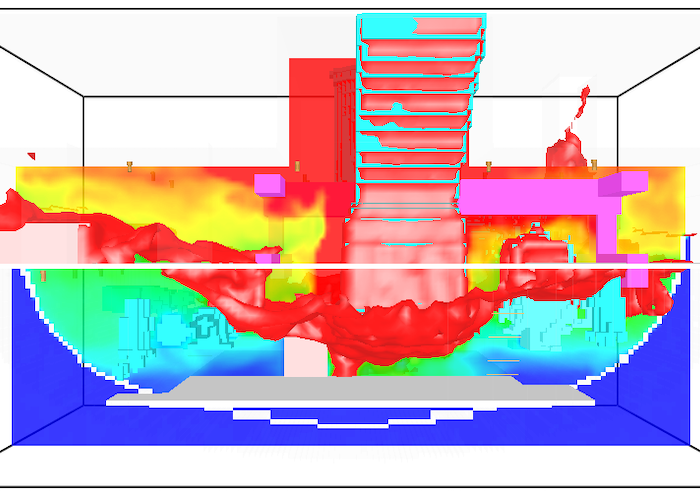

- Fire and Blast Engineering

- Safety Management Systems (SMS)

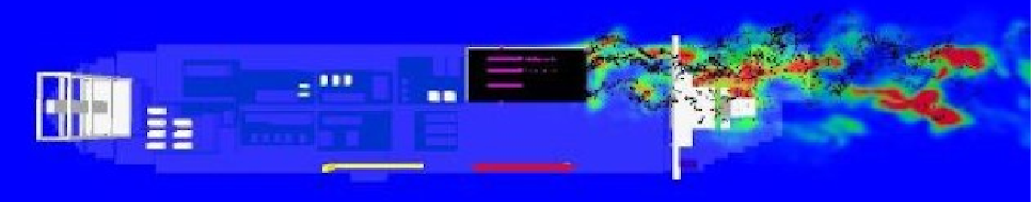

- Consequence Modelling (gas, fire, smoke)

- Software Safety

- Software Safety incl SIL Assessment

- COMCARE Approved Assessor for Major Hazard Facilities (MHFs)

- System Safety Engineering Training Courses

Visit our list of project experience for more information.

A Safety Case is the means of demonstrating that an activity or operation will be safe and without undue risks to people or property and that all practicable steps have occurred to ensure this. The concept of a Safety Case is enshrined in Australian legislation and is supported by ABR6303 and AAP7001.054.

The development of an appropriate scope and content for a safety case is a critical task and requires a thorough understanding of the overall safety intent and activities. It is essential to define and establish a robust safety case early on in the development program to ensure suitably qualified evidence is generated and gathered to support and justify the final safety case argument.

AMOG has extensive experience in the development of complete Safety Cases or alternatively is well placed to assist in:

- The overarching safety case argument structure

- The development and auditing of Safety Management Systems

- Developing supporting arguments that all hazards have been adequately addressed and relevant safety requirements met

- Providing guidance and rationale for safety assessment methods and criteria employed

- Effective management in the production and management of Objective Quality Evidence (OQE)

- Providing expertise in current regulatory compliance levels and justification for any associated deficiencies

- AMOG has assisted clients in different sectors to develop safety cases for regulatory approval:

- Onshore Major Hazard Facilities (MHFs)

- Rail

- Defence

- Offshore Accomodation Vessels

- Offshore drilling and production vessels and platforms

- Offshore pipelines and cables

A Safety Management System (SMS) is core to any Safety Program and fundamental to providing evidential support to any safety case claims. The importance of a comprehensive SMS, as a significant element of delivering safe systems, is reflected in most onshore and offshore regulations covering dangerous goods or hazardous chemicals, and contemporary supporting standards. As well as setting a foundation for any safety claims, an SMS provides the basis for ongoing operational safety management activities, and is an important part of ensuring continued compliance with safety objectives. It also fulfils the need to demonstrate continuous improvement.

- Defining Policies and Plans

- Developing Safety Guidelines, Procedures and Forms

- Defining Safety Policies and Processes

- Defining Roles and Responsibilities

- Nurturing the Safety Culture (Employee Involvement)

- Legislative Compliance Claims

- Defining Safety Critical Elements and Performance Standards

- Verification Schemes

- Integration of related Risk Management Activities

- Integration of Safety into Change Control Processes

- Producing Hazard Tracking (Registers/Logs)

- Incident Reporting and Investigation

- Auditing and Measuring Performance

- Employee Competency and Training

- Constructing Safety Management Plans

- Safety Case Documentation Production

- Emergency Response Plans

- Quality Assurance

SYSTEM SAFETY ENGINEERING COURSES

The demand for superior technology and increased efficiency in modern systems has resulted in substantial escalations in the sophistication and complexity of new designs. This has resulted in a significant increase in the reliance on modern, software intensive control systems that are extremely complex and can include any number of potential safety critical failure modes.

Acknowledging this challenge, international and domestic governing and regulatory bodies are requiring comprehensive and robust demonstrations of how safety has been considered for these systems – from concept to disposal.

The role of the System Safety Manager and Safety Engineering Specialists has therefore become critical in ensuring potential failure modes are examined in a robust, repeatable and audit-able manner to ensure that safety risk is understood and assurance is demonstrated.

Over more than 10 years, AMOG has trained over 600 engineers in the area of System Safety with our 5-day System Safety Engineering Master Class and, more recently, our 5-day System Safety Engineering Application Course.

We are not currently running any public courses. These courses are offered to Government Departments and private companies only – please contact us to find out more .

FACILITATORS

Cherie Holland MSc (Mechanical Engineering), BSc (Mechanical Engineering), MIEAust, CPEng, NER, RPEQ

Cherie has worked across a variety of Australian Defence Force and civilian projects providing expertise in technical analysis, system safety engineering and health hazard assessments. Previously, Cherie was employed in the aerospace industry in the USA and has experience in structural design and analysis of Intercontinental Ballistic Missiles with expertise in technical analysis. Cherie is a specialist health hazard analyst where she brings expertise in the areas of hazard identification, environmental and operational risk, use of Codes of Practice and Standards, and qualitative and quantitative risk assessments.

Kevan Young BSc (Electrical Engineering), MIEAust, CPEng, NER, RPEQ

Kevan T. Young is a Principal Engineer with AMOG and has over ten years working in the Safety Engineering and Human Factors industries; and over twenty years of experience overall including work in the US Navy and commercial nuclear industries. He has extensive experience as a nuclear engineer and operator in the Navy Submarine Force and in providing nuclear engineering services to the commercial nuclear industry. His areas of focus have included: System Safety; risk assessment; hazard analysis, I&C troubleshooting and repair; Human Factors (HF) and Human Engineering (HE); error analysis; nuclear systems and electrical safety procedure revision; safe shutdown analysis; Multiple Spurious Operations (MSO) analysis; circuit analysis; electrical design and modification review; fire modelling; and NEI 12-06 Flexible Coping Strategies (FLEX) analysis support for natural disasters at nuclear plants.