DIGITAL ENGINEERING SOLUTIONS

AMOG have been working at the cutting edge of combining sensor technology with engineering expertise to deliver solutions to challenging technical problems. By combining strong capabilities in data science and machine learning with specialised domain knowledge, AMOG is poised to enable its clients to harness the power of Industry 4.0 to understand how their assets work.

We provide improved solutions to optimise operations and maintenance practice and minimise risk, including;

- Condition monitoring

- Real time condition assessment

- Tuning of asset performance

- Forward predictions of remaining life

Products

Click on the tabs above, or on the individual product name, for more information.

For decades, mining plant and structures have failed before their design life is reached, sometimes unexpectedly, resulting in costly disruptions and even loss of life. With the aim of extending design life or increasing utilisation, plant designers, suppliers and owners continue to identify different plant operating conditions relative to the original design assumptions. Often, they are unable to understand the knock-on effects of these changes due to lack of accurate data.

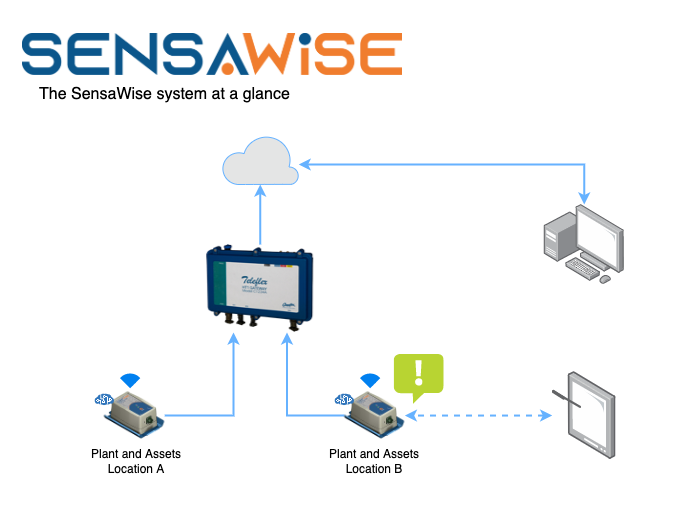

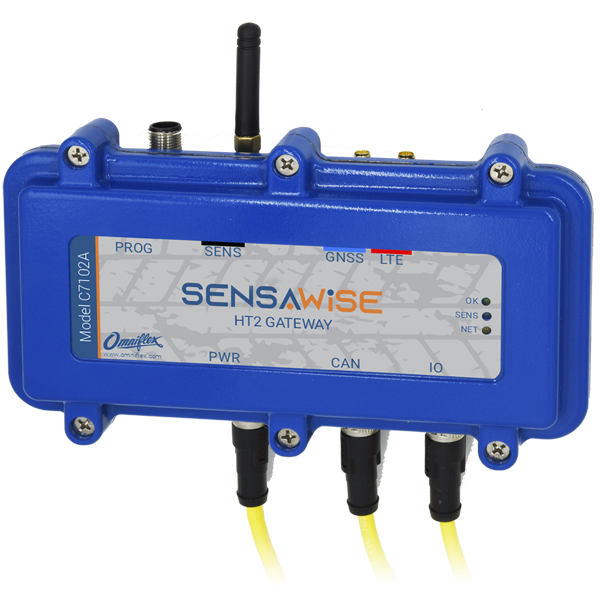

AMOG’s SensaWise solutions bridge the missing link between gathered sensor data and useful operational feedback in a single holistic package. The SensaWise system, which can be installed on existing assets, gathers data which is fed into digital twins of the asset and used to monitor plant and structural response, relative to design, in real time. SensaWise nodes with their edge processing capabilities can identify failures in real-time, monitor and relay data and pro-actively manage alarms and integrate with control systems.

Blasting can yield uneven fragmentation of ore, resulting in large pieces of rock called “oversize”. In most instances in open cut mining, oversize material is excavated and transported to the Run of Mine (ROM) area and processing plant by haul trucks. The oversize material then collects in ROM bins or chutes forming blockages as it is too large to feed into the primary crushers. The oversize material impedes the flow of ore, reduces production rates, and can completely block the inlet to the primary crusher causing a shutdown of the plant whilst the blockage is removed. This causes costly delays in production, damages crushing equipment and introduces safety hazards to maintenance personnel when removing the blockages.

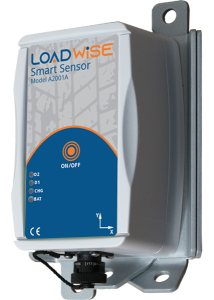

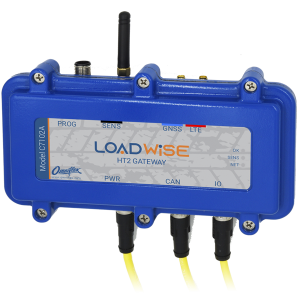

LoadWise is a system designed for data gathering in haul truck applications. The LoadWise system is designed to be scalable such that it can be implemented on a single truck or rolled out across an entire fleet. With the scale of the deployment defined, system components can be retrofitted onto the selected haul truck(s). The system operates in real time to detect and alert when oversized loads are loaded onto the instrumented haul trucks. The outputs from the LoadWise system can assist in improving truck-routing decision-making, which can reduce crusher blockages and optimise crusher throughput.

Though the system’s core functionality is for oversize detection, the system can be extended to perform other functions such as human vibration tolerance monitoring for haul truck operators and road condition monitoring.

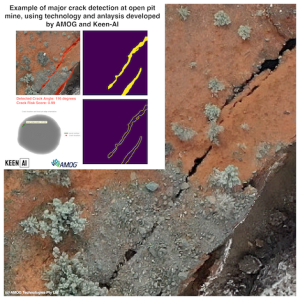

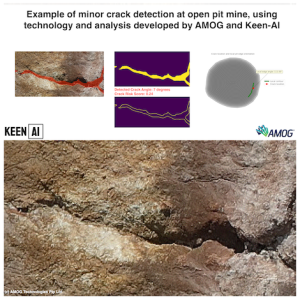

SLOPEWISE - early crack detection

AMOG and Keen AI have developed early crack detection technology to deliver improved safety to mine-sites, dramatically improving the geotechnical risk management of mine open cast pits.

With the potential to cause multiple fatalities and stopping a mine for months, pit slope failures are a serious safety and business risk. A recent paper produced by a major miner documented 185 incidences of slope failures at West Australian-based open-pit mines [1] – the challenge is significant.

To manage safety risks, early detection of precursors is vital. They allow mine-sites time to plan and take action to avoid catastrophic events. Mine-sites using early detection better comply with regulatory goals, both with critical risk management and effective safety systems.

AMOG and Keen AI both have extensive experience in early detection. AMOG has developed early detection of large rock blockages, using machine learning applied to haul truck tray vibration signatures and other similar detections using digital information at mines, ports, refineries and petrochemical facilities. Keen AI uses early indicator detection through visual indicators, detected using machine learning of images of electrical systems and more.

AMOG and Keen AI have developed a pit slope precursor to a failure detection system, with the assistance of Element Geospatial. This system uses drone data, whether collected by the mine site operators or another supplier, to accurately detect and monitor tension and shear cracks associated with pit slope failures.

Using a variety of deep learning and computer vision algorithms Keen AI, with AMOG input, has developed and trialled the detection on several mine pits. It can currently detect tension and shear cracks in drone images with a high degree of accuracy.

- Better met regulatory requirements - the detection and monitoring system assists mine sites in meeting the regulatory need to detect, monitor and manage slope instability risks

- No additional flights needed - drone data becomes useful for digitally assessed risk assessment and there is no need for additional flights needed

- Less manual reviews - no need for field observations or attempting to detect cracks by manually reviewing hundreds of images - the detection algorithm is more accurate than these techniques and is expected to become even more accurate with time

- Intuitive reporting geared for action - the dashboard that presents results is intuitive and gives users a ranking of risk areas to help prioritise actions

- Change monitoring - once a site's pits are assessed and areas of interest detected, subsequent flight data is used to detect any change, especially when events that can trigger slips occur (such as rainfall, blasting or seismic events, and heavy equipment traffic)

The detection and monitoring system allows geotechnical teams to focus on solutions for problem areas – this quicker response can save lives, time and costs. For more information, contact Richard Shedlock (AMOG Perth +61 8 9212 1800) or Hayden Marcollo (AMOG Melbourne +61 3 9542 3700), or the team at Keen-AI.

AMOG’s deep knowledge base and subject matter expertise in offshore energy and integrity management, coupled with our digital capabilities, allow us to provide cutting-edge solutions to help enable safe and reliable access to the world’s offshore energy resources.

Our suite of digital products for the offshore energy industry is led by AMOG’s Smart Mooring Integrity Checker (SMIC), the world’s most advanced integrity monitoring platform for floating assets, which is already saving operators in operations and maintenance costs and improving risk management practices.

Furthermore, AMOG offers its clients a highly developed capability in dynamic vibration monitoring of offshore structures. This industry-recognised capability is founded upon the combination of experience gained from many years of offshore structural vibration monitoring and analysis, utilising state-of-the-art vibration measurement tools and in-house developed software for vibration analysis.

AMOG is able to support clients by offering the following services relating to condition monitoring:

As an island nation, Australia’s ports and wharves are strategically critical infrastructure, serving two key and vital purposes; the economically indispensable junctions for global supply chains, and homes to the seafaring assets essential for our country and coastline’s sovereign defence. There are more than 70+ ports around Australia for both imports and exports and, according to Ports Australia, AUD$1.2 billion of trade (98%) moves through Australian ports every day.

Throughput in Australian ports covers general, bulk, and container cargo, as well as motor vehicles. Vessels that visit the ports are largely commercial though also include navy (RAN and visiting navies), as well as cruise vessels and ferries. They generally spend 2 to 48 hours alongside, with the exception of navy and cruise ships, which often spend longer.

Despite such an essential role, port and wharf infrastructure, subjected to harsh marine conditions, often has little redundancy and requires significant capital investment for repair and replacement. These capital costs are often amortised over very long service lives to even enable the initial capital investment. Maintaining their integrity and capacity throughout their planned life (and beyond) is therefore of paramount importance.

WharfWise is a flexible monitoring solution that provides independent diagnostics, validation, and oversight on the performance of critical wharf infrastructure. It provides real-time load monitoring through an online interface, with automated notifications and alarms to alert operators when load conditions are approaching or exceeding preset thresholds. AMOG, in partnership with remote monitoring specialists Omniflex, can supply WharfWise for new or existing port infrastructure as a turnkey monitoring solution.