MODELLING & ANALYSIS

Leading edge engineering design and analysis in specialist fields are at the core of AMOG’s services. Drawing on theoretical and practical insights, our teams thrive on the application of advanced analysis techniques and design practice to solve complex engineering problems.

Specialist areas of application include:

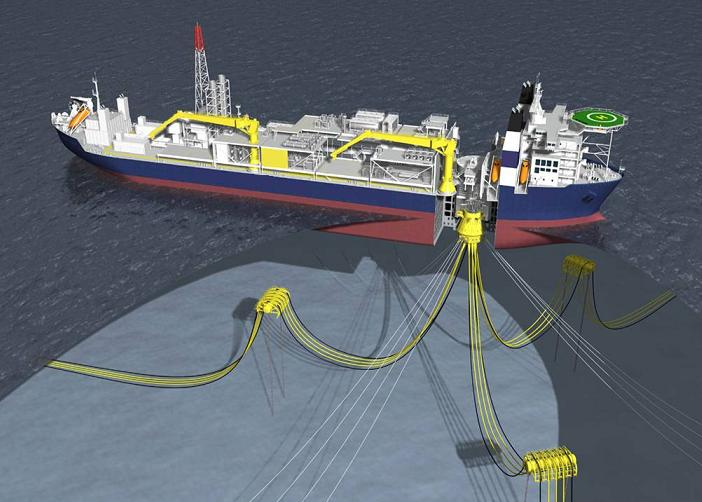

- Floating production systems (moorings, risers, turrets, swivels, platforms)

- Aged fixed production platform structures

- Subsea pipelines and submarine cables

- Offshore renewable energy sources

- Numerical modelling of fire and blast effects

- Seawater intakes

- Consequence Modeloing

- Computational Fluid Dynamics (CFD)

- Hydrodynamics

- Ocean Outfalls

- Bulk material handing equipment

- Rope technology

- Exhaust and discharge dispersion

- Seakeeping

- Mine blast effects

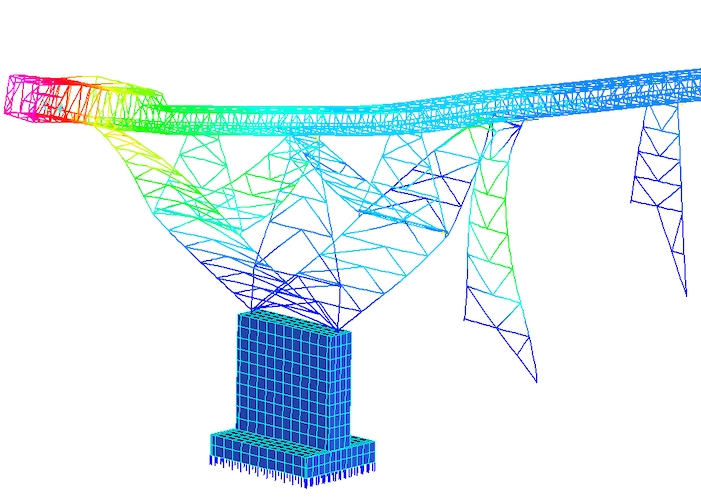

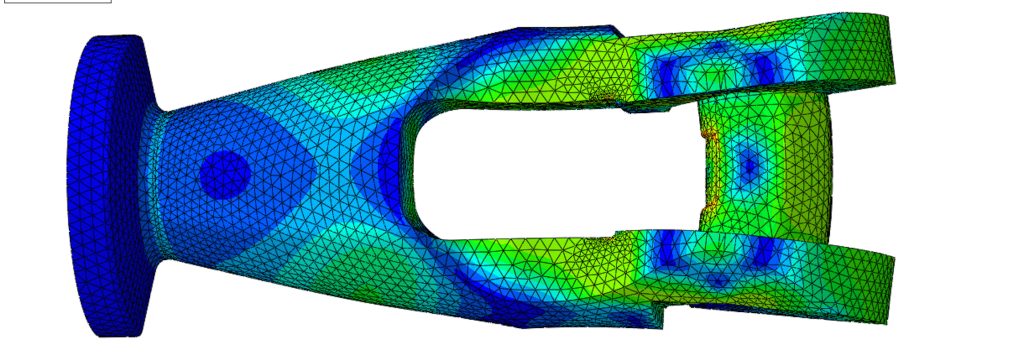

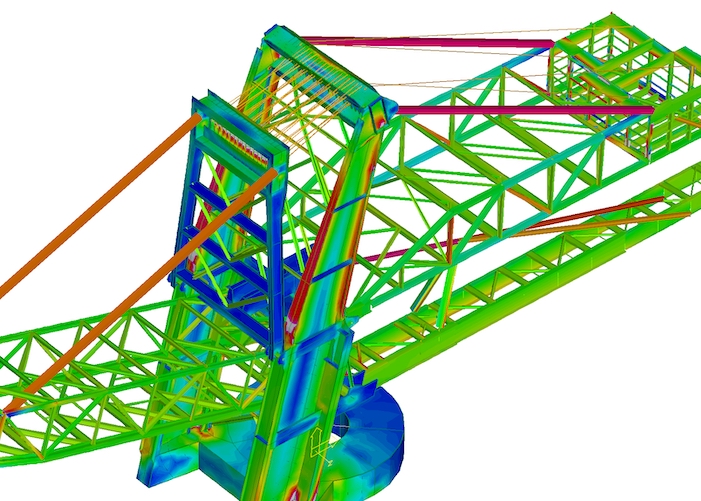

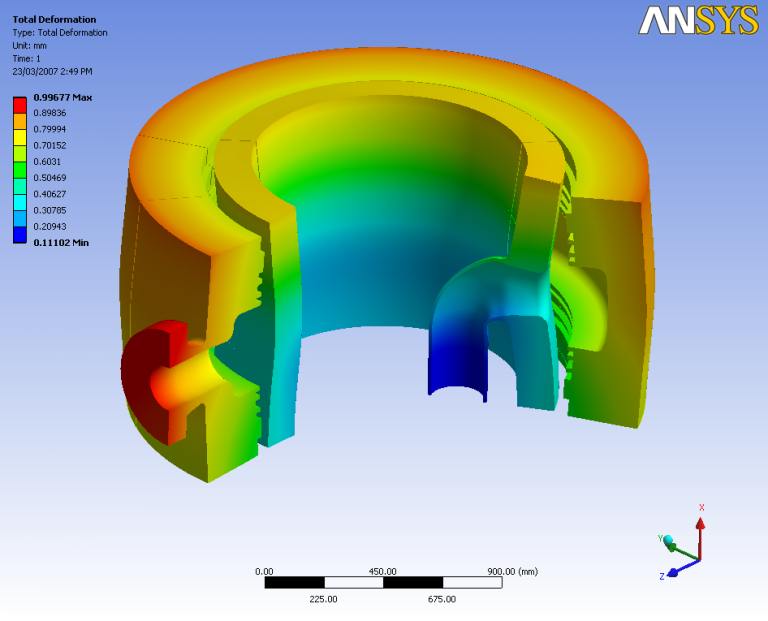

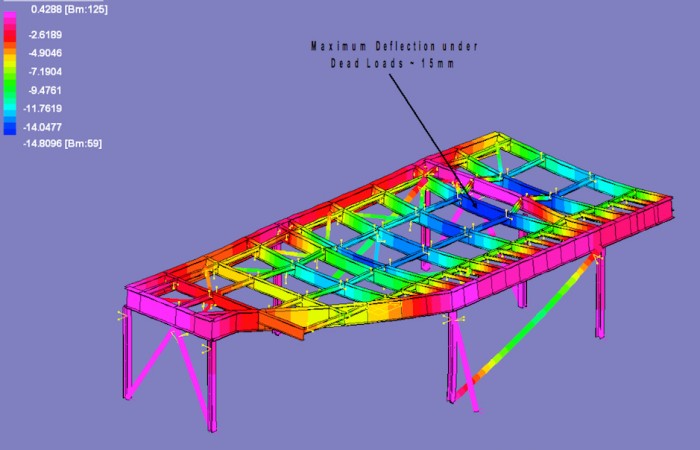

- Finite Element Analysis (FEA)

- Vortex Induced Vibration (VIV)

- Scale Model Testing

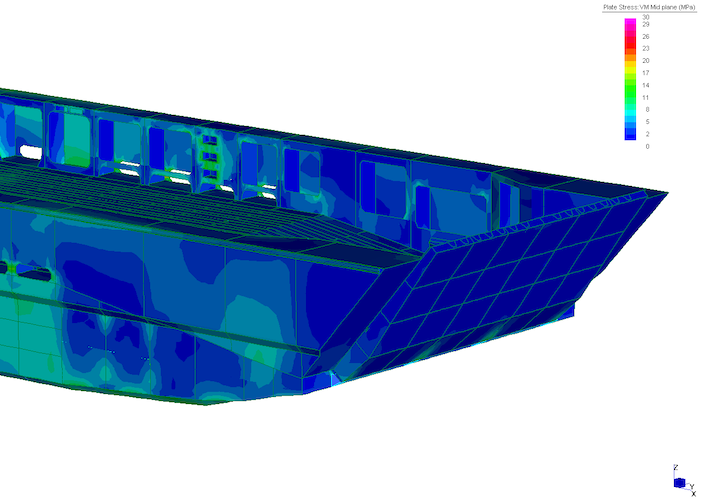

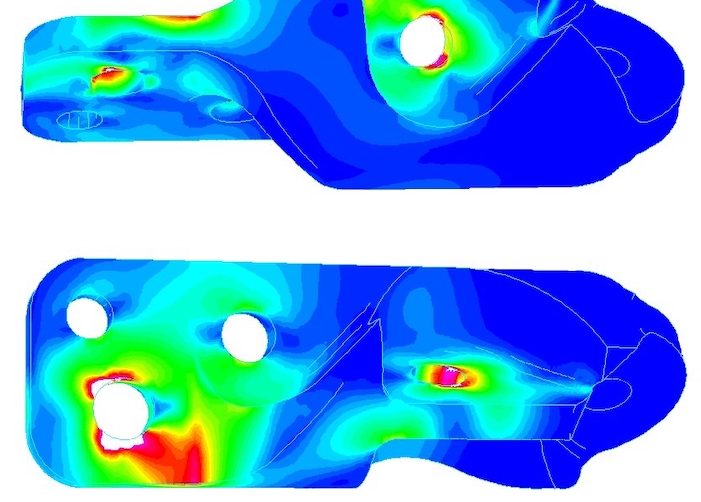

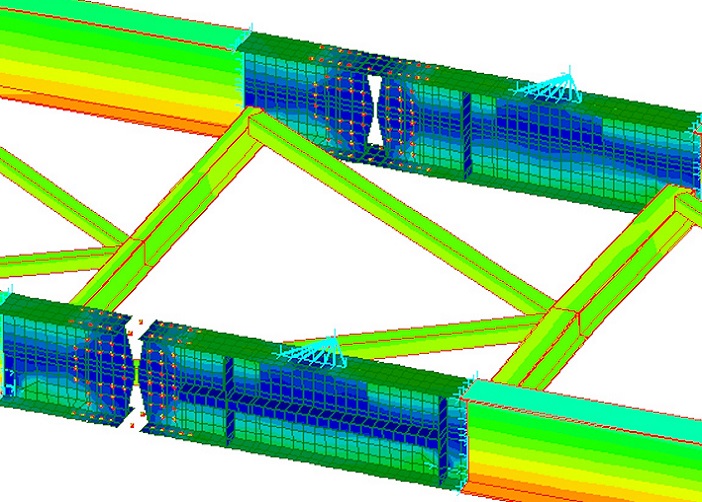

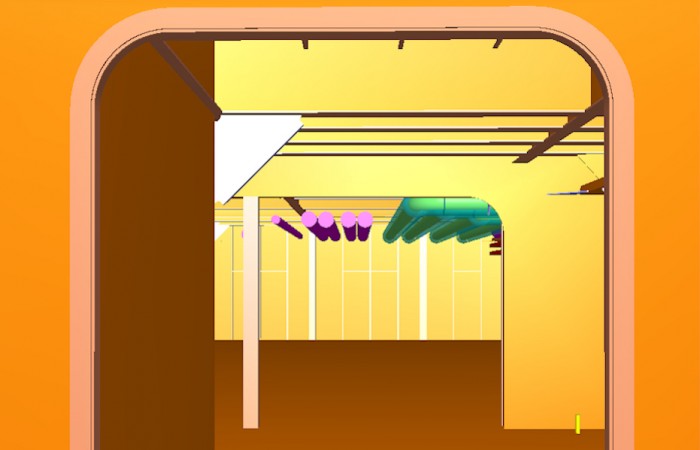

AMOG Consulting is able to undertake advanced engineering analysis and detailed design of marine based structures and systems. Using state-of-the-art analytical packages, AMOG can design complex offshore and onshore structures/components requiring non-linear solutions incorporating:

- Non-linear geometric and material properties

- Multi-component contact interaction and friction

- Large and permanent deformation

- Fluid loading

- Thermal loading and creep

AMOG Consulting is able to support clients by offering the following services:

- Design of Offshore & Onshore Structures/Components

- Fracture Mechanics Assessments

- Fatigue Assessments, Life Extension & Structural Upgrades

- Impact Assessments

- Structural Assessment of Sloshing Loads on Storage Tanks

- Hydrodynamic Loading of Structural Systems

- Structural Assessment of Dynamic Systems

- Structural Design Appraisal, Reassessment & Third-Party Audit

- Condition Monitoring & Instrumentation of Structures

- Failure Investigation

- Design Drafting

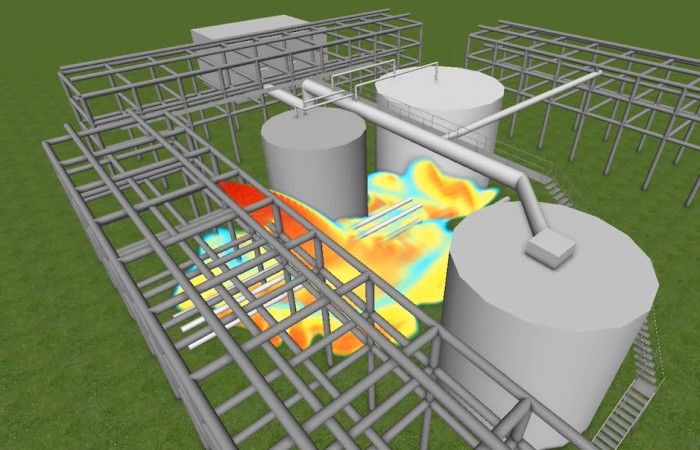

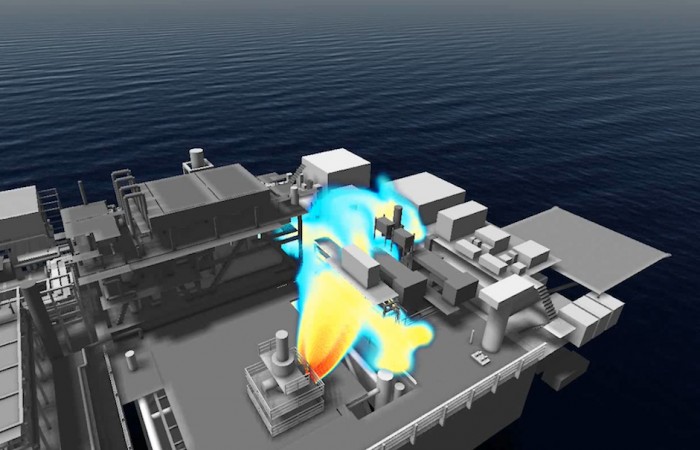

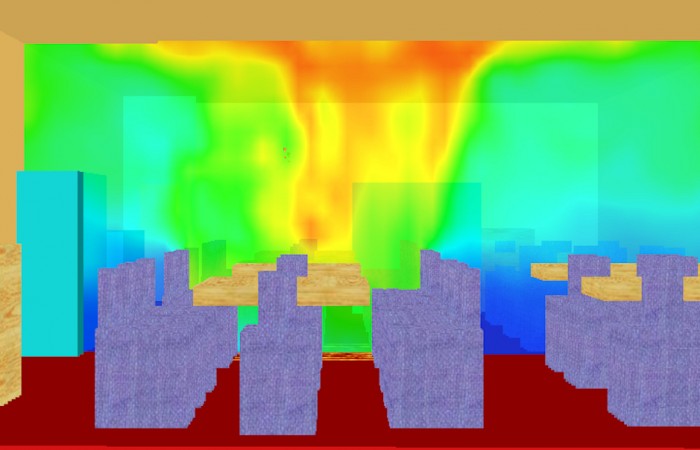

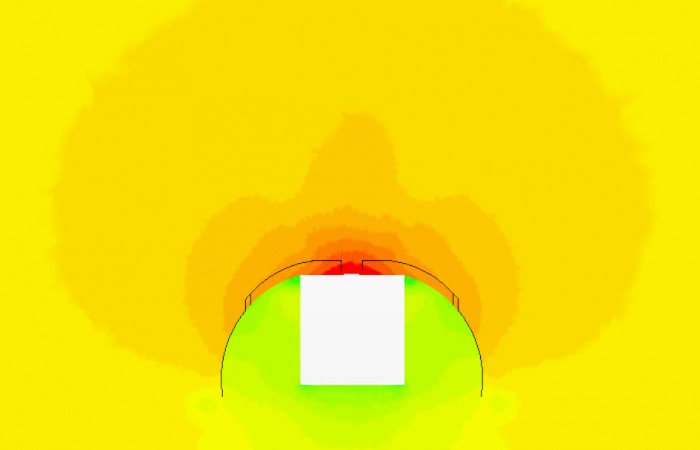

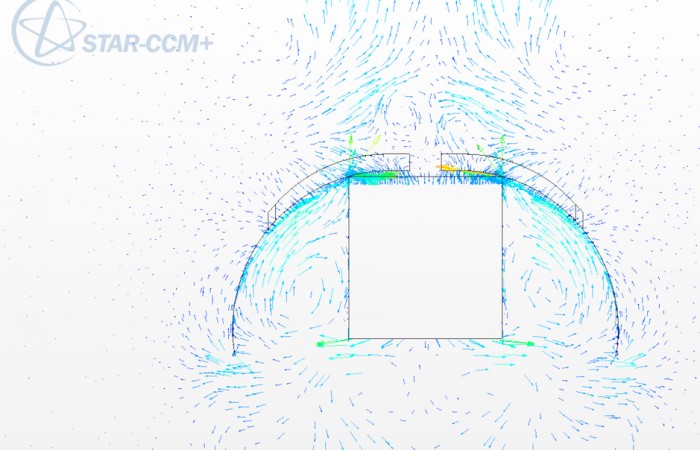

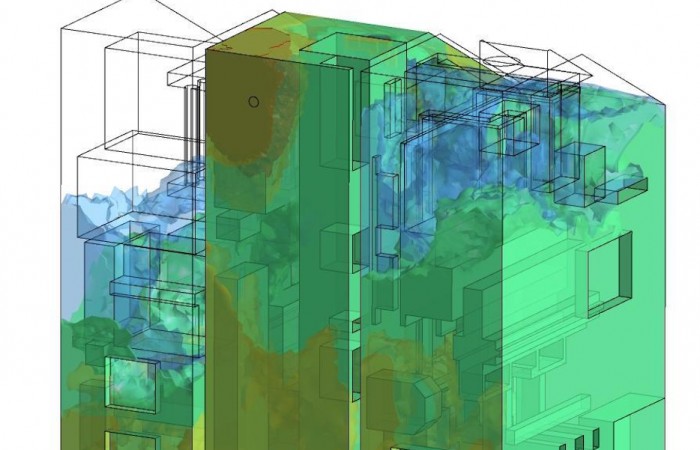

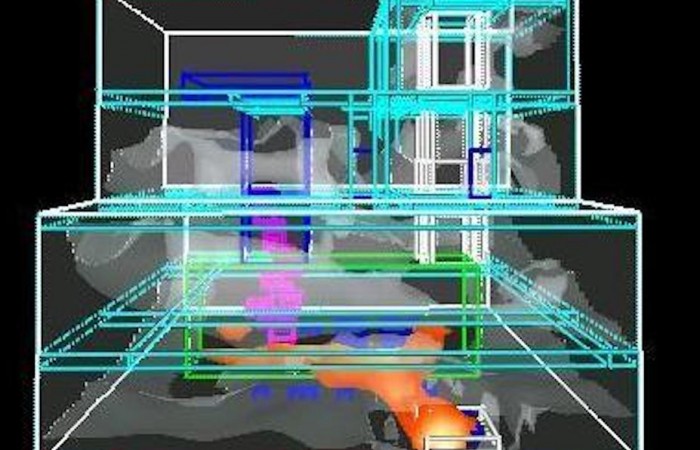

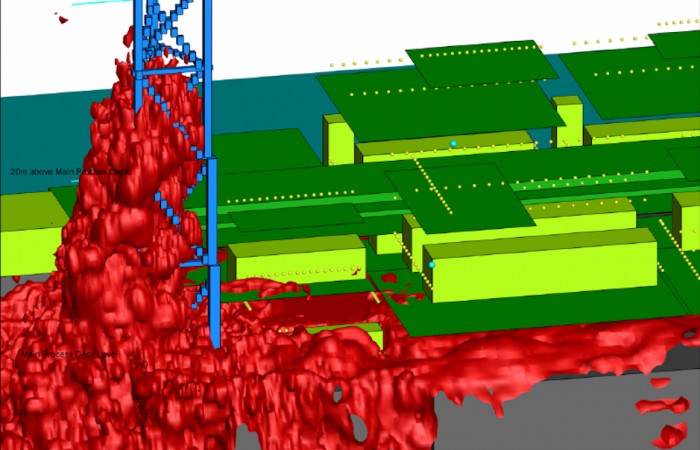

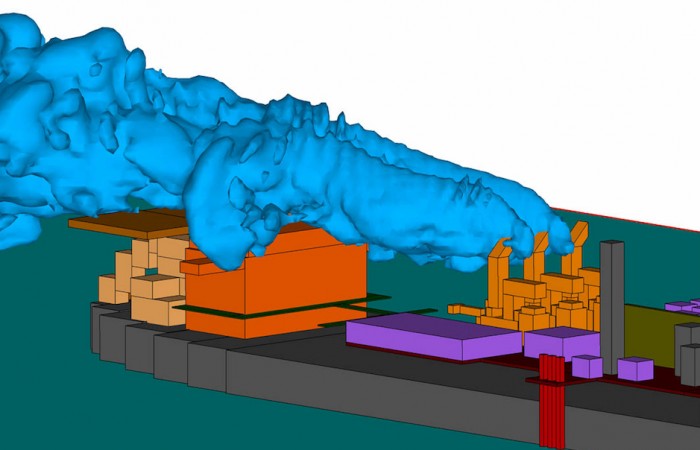

AMOG is able to undertake advanced Computational Fluid Dynamics (CFD) analyses, numerically modelling air flow, fluid flow, fire, smoke, exhaust gas and toxic plume dispersion. AMOG operates a suite of CFD packages, enabling the analysis of various engineering systems in a wide range of flow regimes, including:

- Low and high speed flows

- Thermally driven flows

- High Mach and Reynolds Number Flows

- Multi-phase (including free surface) flows

AMOG has applied CFD capabilities to a wide range of projects including analysis of flow over ship hulls, ventilation flow through electrical cabinets, gas plume dispersion of ship exhausts and on-board generators, tank sloshing fluid loads and high pressure/temperature fluid flow through a turret mooring swivel.

We can provide modelling, simulation and CFD analysis of:

- Air Flow

- Fluid Flow

- Multi-phase Flows

- Fire and Smoke

- Blast Explosion (Gaseous and Dust)

- Fluid Loading

- Heat Transfer and Combustion

- Gas and Toxic Plume Dispersion

- Environmental Flows (Airborne and Water/Ocean)

- Hazard Consequence Modelling

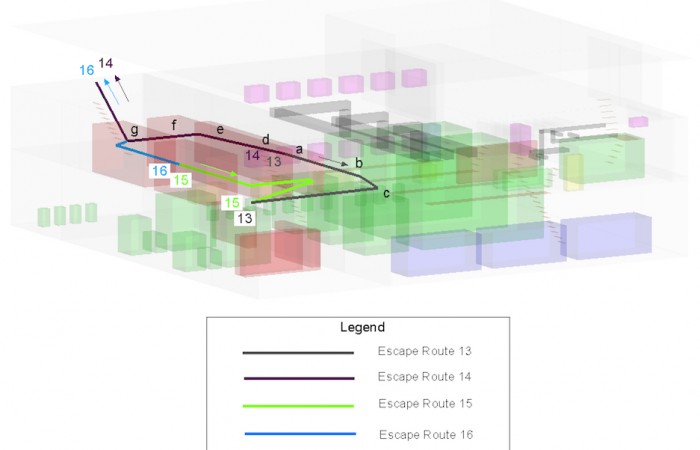

- Assessment of Safe Evacuation Routes and Time

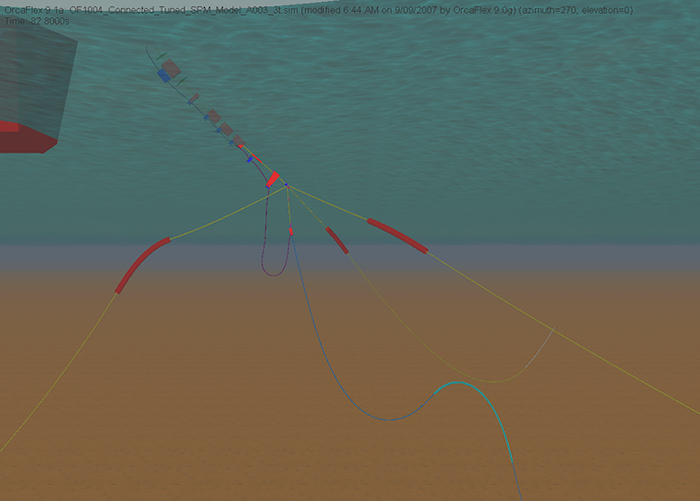

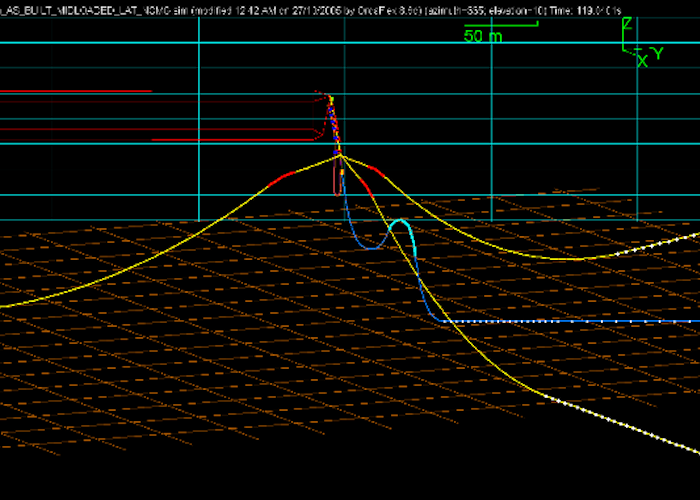

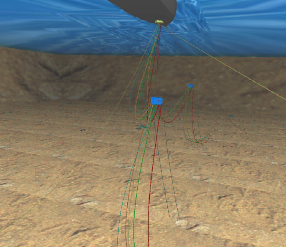

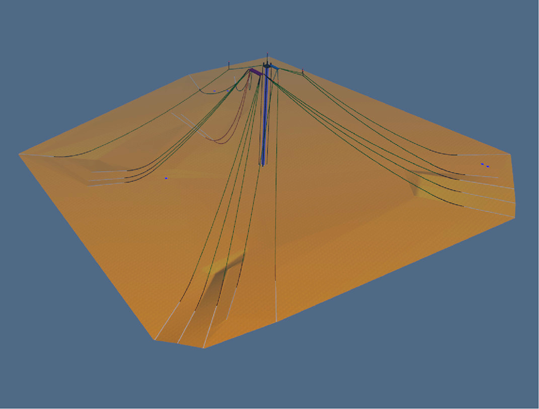

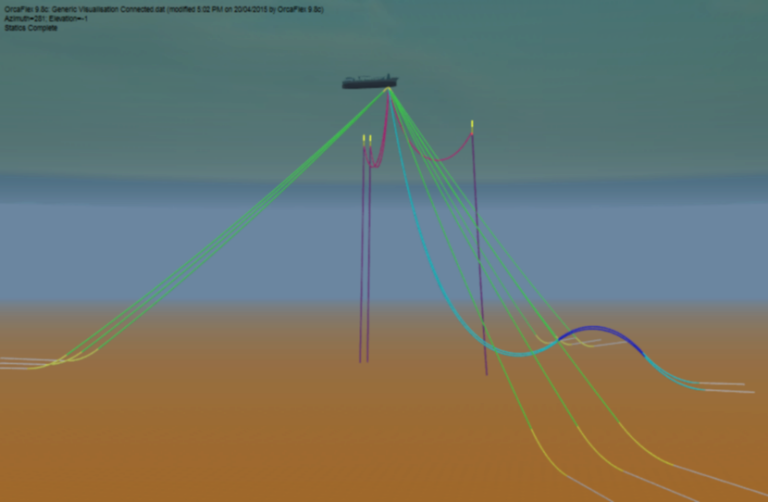

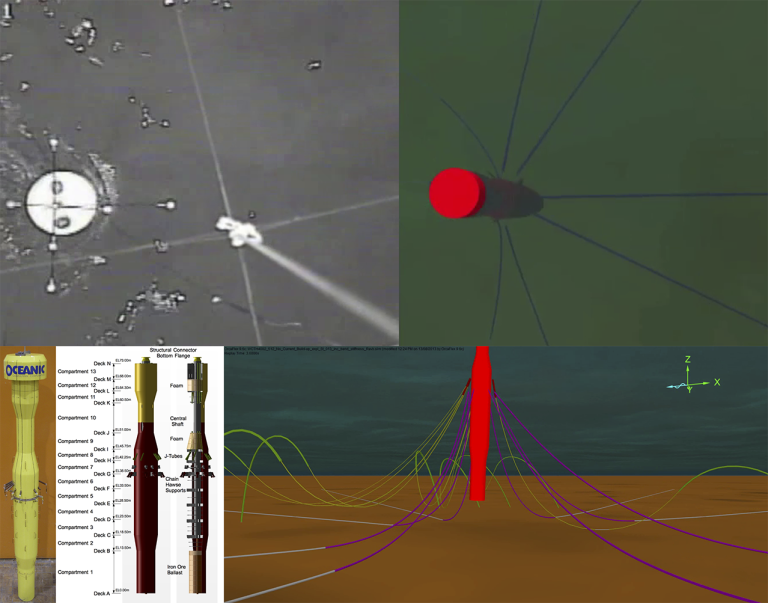

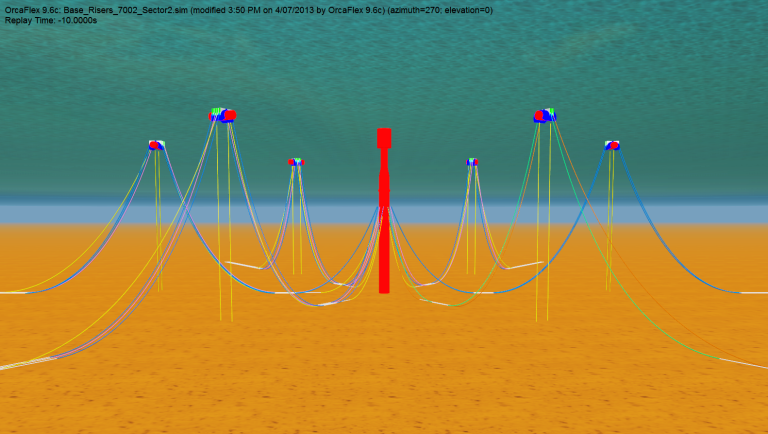

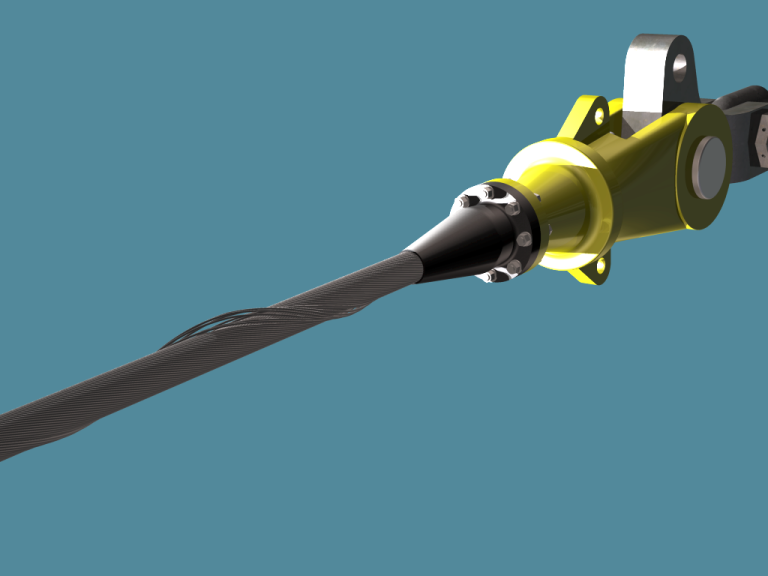

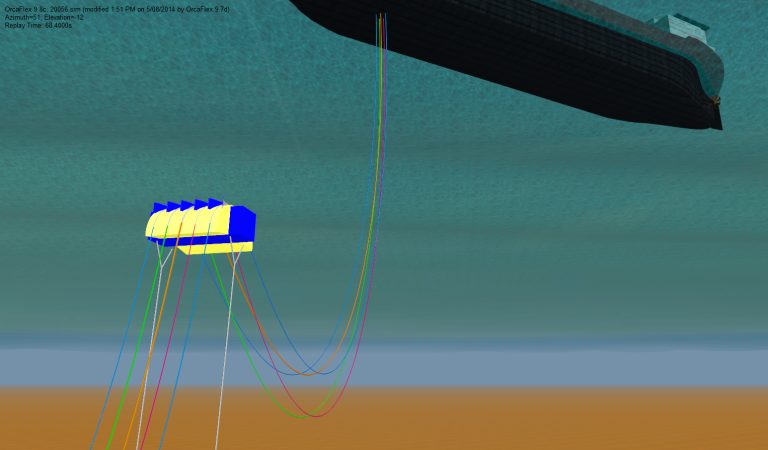

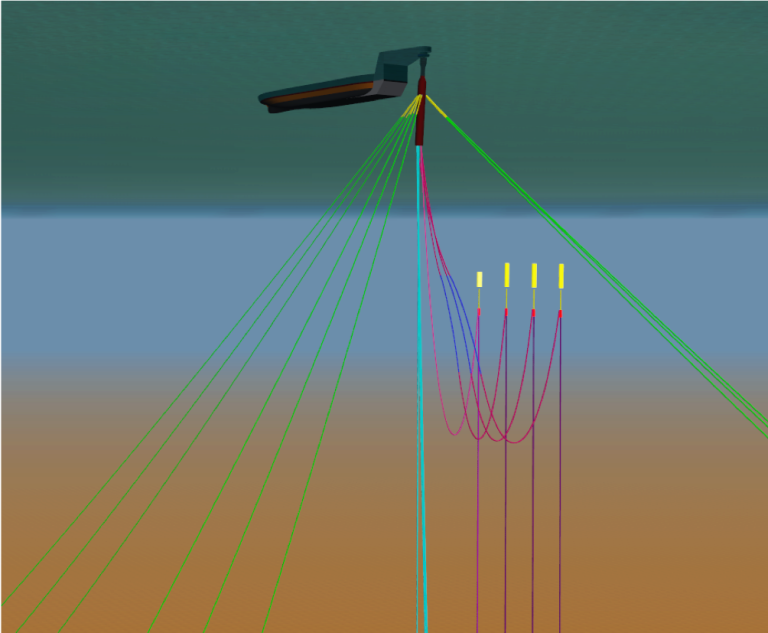

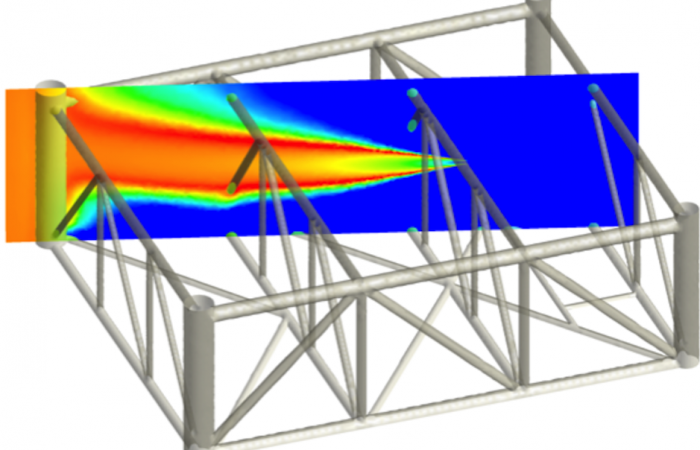

AMOG is able to perform detailed dynamic analyses for multiple line systems using state-of-the-art cable dynamics packages and the industry standard, benchmarked VIV prediction software, SHEAR7.

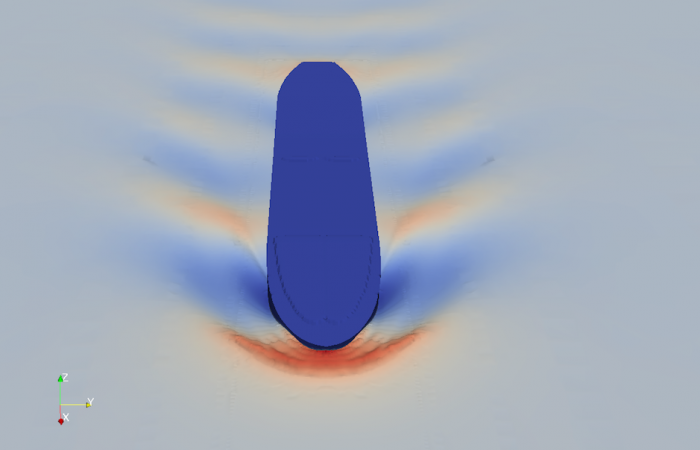

Vortex-Induced Vibrations (VIV) are vibrations caused by the natural shedding of vortices from a body exposed to flow. Offshore structures exposed to flow, particularly long slender structures, are renowned in the Oil & Gas industry for undergoing VIV which can be damaging to the structure, so much so that in some cases VIV is the dominant driver of fatigue.

AMOG has a wealth of experience analysing structures for their VIV responses and performing fatigue life predictions, calculations on drag force amplification due to VIV, as well as benchmarking common industry VIV prediction software such as SHEAR7, VIVA, and VIVANA against laboratory testing.

AMOG is able to perform:

- Concept Definition Studies & Support

- FEED Studies

- Full Field Detailed Design

- Verification Support

- Dynamic Analysis of Riser Systems

- Riser, Hose and Umbilical Integrity Management

- Riser & Umbilical Ancillary Selection

- Riser Fatigue Assessments

- Riser Design Modification

- Mid-Water Arch Design

- VIV Analysis & Suppression

- Riser Installation Analysis

- Materials & Insulation Selection

- Mooring / Riser Clashing Analysis

AMOG is the JIP Manager and distributor of SHEAR7, the offshore industry’s leading software tool for the prediction of Vortex Induced Vibration (VIV)

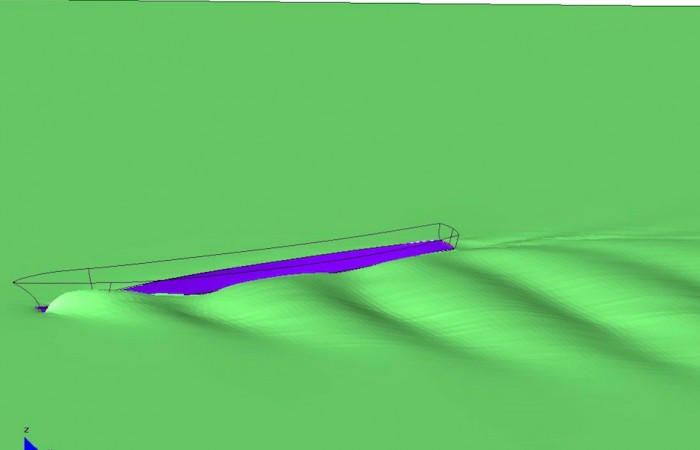

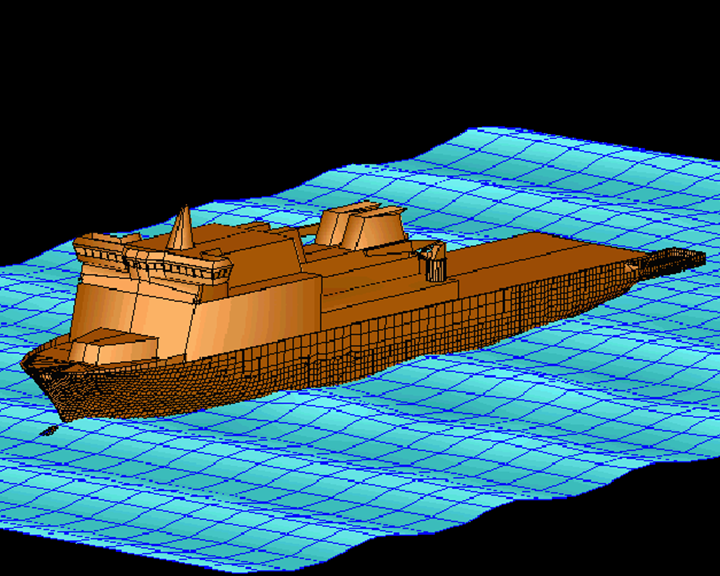

AMOG has extensive experience in all aspects of hydrodynamic analysis for small and large vessels, as well as moored floating offshore structures. AMOG has undertaken studies for a number of major defence and civilian maritime companies, government regulatory bodies, and has undertaken numerous projects in the commercial oil and gas sector. AMOG’s extensive hydrodynamic analysis experience ranges from sea keeping assessment, to design of moorings, greenwater analysis, uptime analysis and structural loads associated with vessel operations. Previous analyses have included both single and multi body configurations, and have addressed vessel motions in extreme seas and in confined waterways.

Based on previous project experience, AMOG is able to advise clients on:

- Hydrodynamics of Coupled Floating Bodies

- Vessel Response in Extreme Sea-states

- Green Water Analysis

- Forward Speed and High Current Speed Effects

- Vessel Motions and Interaction in Confined Waterways

- Non-linear Mooring Stiffness Effects

- Form, Skin Friction and Mooring Line Drag Damping

- Relative Motions and Forces between Bodies

- Coupling Forces and Hydrodynamic Interaction Forces

- Mean, Low Frequency, Wave Frequency Loads

- Wind, Wave and Current Effects

- Modelling of Stabilisers, U-tanks, Rudders and Thrusters

- Fatigue Analysis of Vessels including Slamming Load Effects

- Numerical Modelling and Scale Model Testing

- Operability Limits based on Crew and Equipment

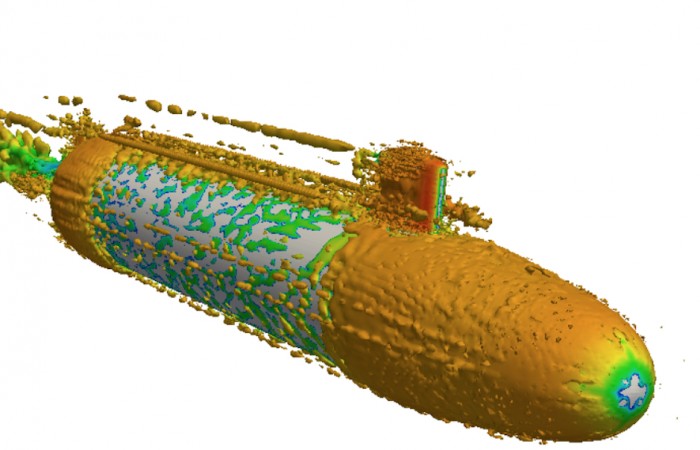

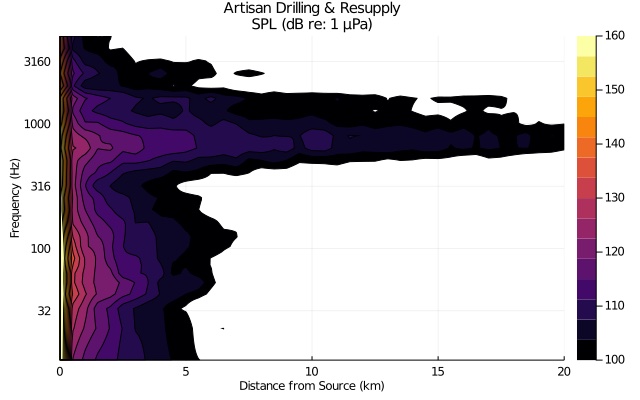

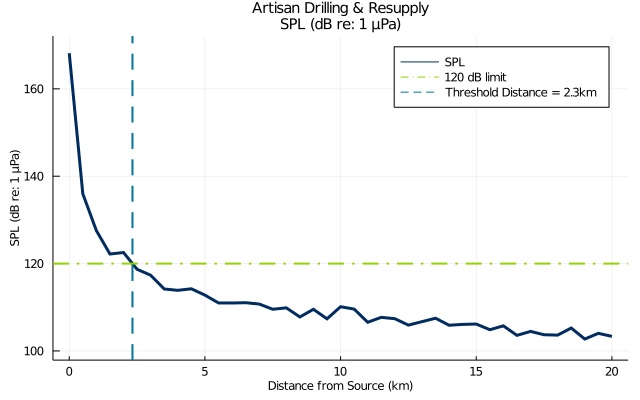

AMOG performs underwater acoustic modelling using techniques which are built upon the U.S. Naval Research Laboratory acoustic models and include in-house AMOG modifications to enable deployment of parallelised algorithms across multi-core clusters on the cloud. It is AMOG’s preference to benchmark predictions against locally acquired field data wherever possible to reduce the uncertainty due to local conditions.

When it comes to physical experimentation, AMOG has a proven track record in delivering successful hydro-acoustic experimentation programs including small & medium scale testing. Roles include supervising university facility staff to run programs right through to running the entire programs. AMOG has had experience designing, building and testing parts of towed sonar arrays and designing and building test facilities.

AMOG has a proven track record of working with global and national companies and organisations including the Australian Maritime College (AMC) at the University of Tasmania, Hydro Tasmania, Monash University and Thales. These skills, capabilities and experience put AMOG in good stead in the underwater acoustic industry of Australia and beyond.

AMOG is able to support clients by offering the follow services in relation to Underwater

Hydro-Acoustic Modelling and Experimentation:

- Marine Fauna Sound Modelling for Environmental Impact Assessments

- General Underwater Hydro-Acoustic Modelling utilising cloud computing

- Modelling noise sources due to cavitation induced by propellors

- Modelling multiple noise sources

- SPL (Sound Pressure Level) and SEL (Sound Exposure Level) assessments

- Independent review of Hydro-Acoustic Modelling Techniques

- Prototyping underwater hydro-dynamic equipment

- Test facility design and build

- Test site feasibility studies

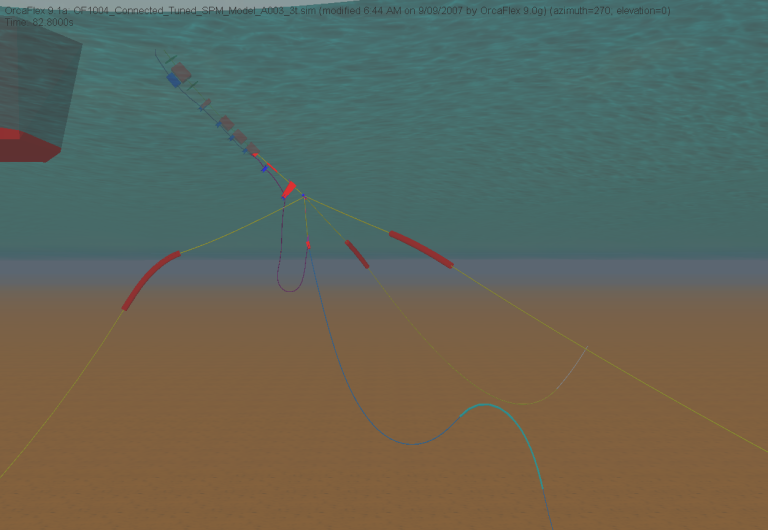

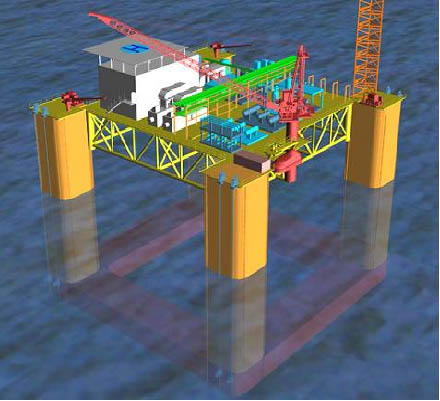

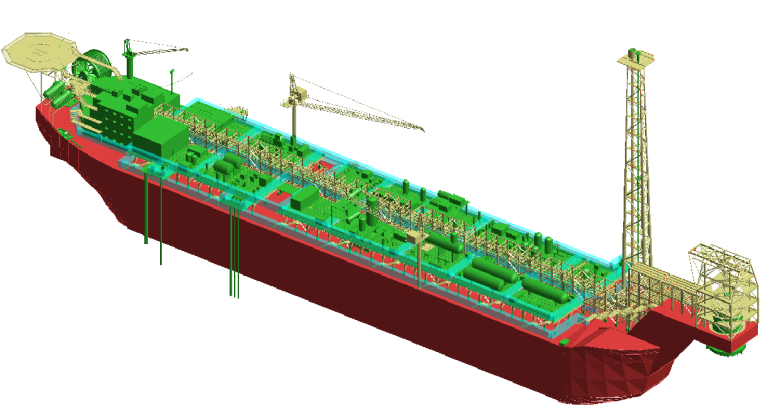

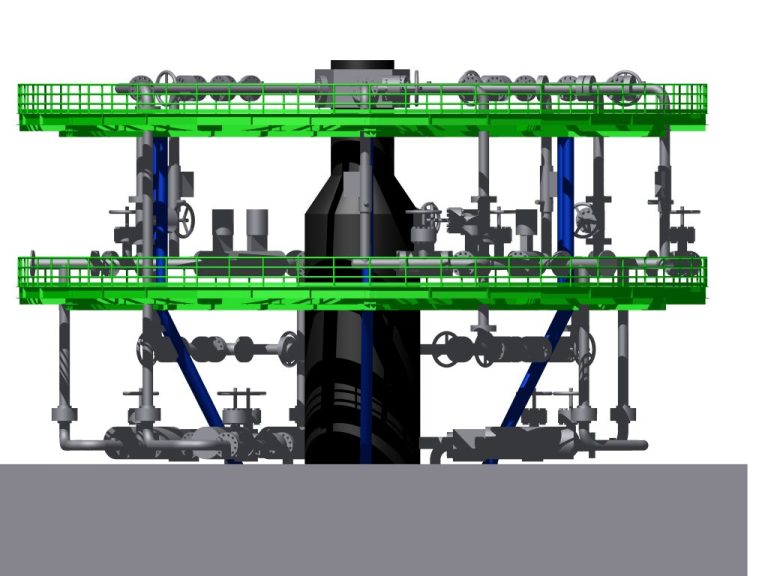

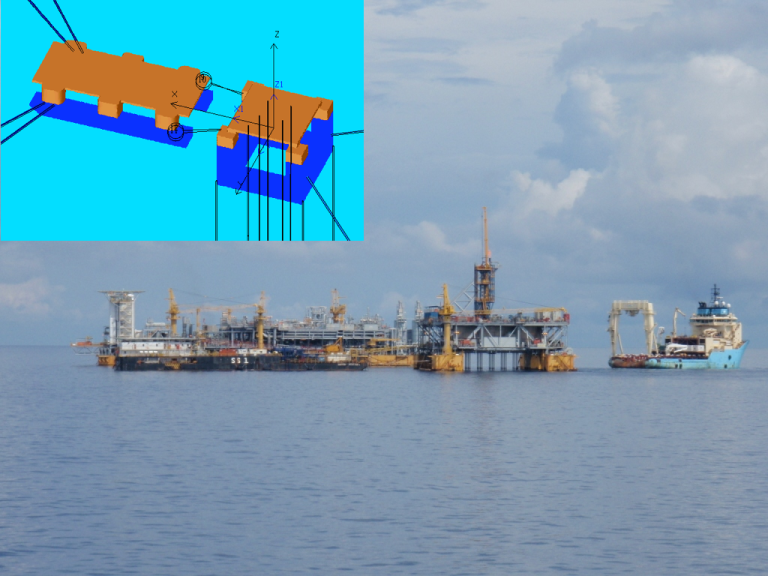

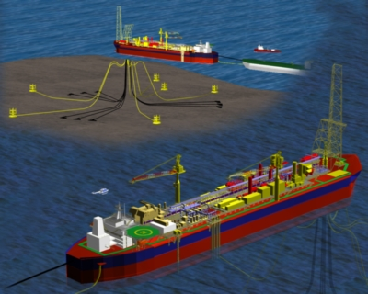

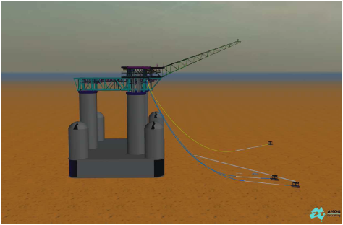

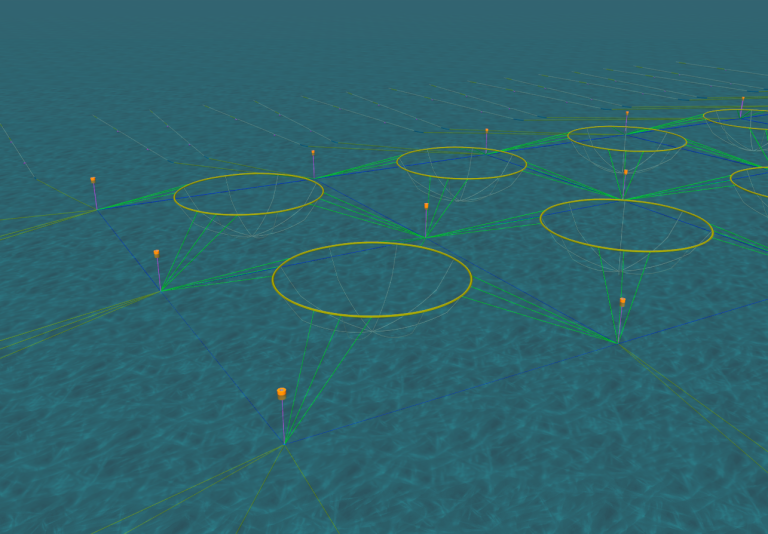

AMOG is able to perform design analyses using advanced numerical techniques and state-of-the-art software, covering a broad range of issues pertinent to the design and installation of mooring systems. AMOG has extensive experience in the analysis of the dynamics of a wide range of hull forms (tanker based FSO/ FPSO, Spar, Semi-Submersible,TLP, Barges, CALM) and riser (flexible riser systems)/ mooring (chain, wire rope, synthetic rope) systems over the full range of water depths,complemented by our model testing capability. AMOG in particular has extensive experience with disconnectable mooring systems.

AMOG can assist with moorings for multiple applications:

- Floating offshore wind (FOWT)

- Wide range of hull forms

- CALM buoys

- Aquaculture

- Deepwater

- Near shore

AMOG is able to support clients by offering the following services in relation to mooring system design:

- Concept Definition Studies & Support

- FEED Studies

- Full Field Detailed Design

- Verification Support

- Dynamic Analysis of Riser Systems

- Permanent and Disconnectable Mooring Systems

- Hull Form Analysis (Hydrodynamic and Hydrostatic) and Selection

- Coupled Body Response Assessment

- FPSO Turret Design Review

- Mooring/Riser Clashing Analysis

- Anchor/Pile Selection

- Mooring System Installation Analysis

- Mooring System Load Monitoring, Fatigue and Integrity Assessment

- VIV Analysis and Suppression

- Metocean Conditions Review

- Uptime Analysis

- Mooring Integrity Management (MIM)

With a long-standing history of excellence, Moorsure specializes in remediating, extending the life, or completely replacing existing mooring systems. We work within system constraints and adapt to changing facility needs. For specialist mooring system design, analysis, and supply, please visit Moorsure.

AMOG has lead a number of international JIPs in this area

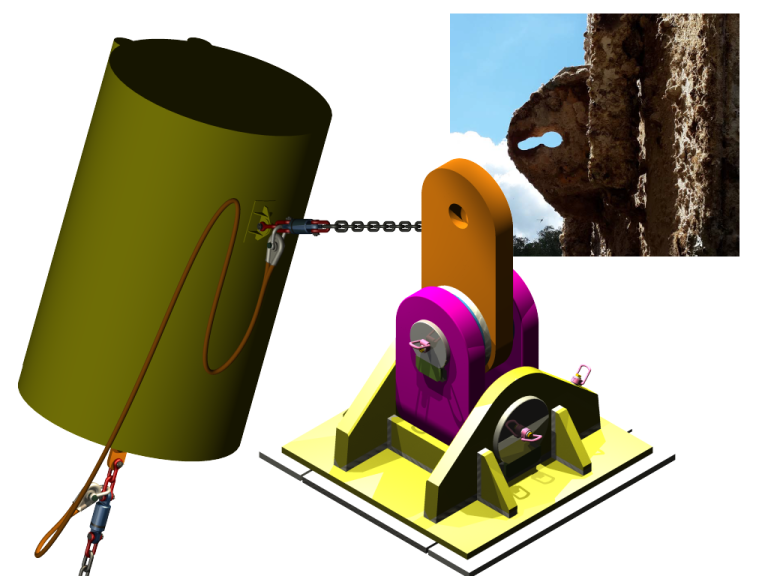

AMOG offers a wide range of physical scale model testing services using AMOG Consulting’s own test equipment and design experience in conjunction with facilities available through Monash University. AMOG can bring to any testing program the experience and intellectual property developed over more than a decade in physical scale model testing for the marine and offshore industries. AMOG Consulting can also provide scale model testing services to address a wide range of issues through the design and construction of purpose built testing apparatus to suit specific requirements.

AMOG is able to support clients by offering the following services relating to scale model testing:

- Model Testing of Subsea Pipeline Stabilisation & Protection Devices

- Model Test Verification Against Numerical Analyses

- Independent Audit

- Wind Tunnel Model Testing

- Wave Flume & Deepwater Model Testing

- Model Testing of Marine / Offshore Structures & Floaters

- Model Testing of Mooring & Riser Systems

AMOG can provide expertise in determining the consequences of fire snd gas explosions including the far field blast wave effects. AMOG has extensive experience in the modelling and simulation of fire and blast events, through both analysis and physical testing. We can perform a fully integrated design process, with the fire and blast modelling and simulation tools used by AMOG, which allow for the incorporation of all system components tat will influence the outcome of a fire or blast scenario including gas dispersion, ventilation systems, fire detection and suppression systems, and blast loading structural assessment. AMOG is able to support clients by offering the following services relating to fire and blast modelling:

- Consequence Modelling & Progressive Collapse Studies

- Fire and Life Safety Case Audits

- Evacuation, Escape and Rescue Support and Modelling

- System Survivability Studies

- Design and Conduct Of Physical Test Fire & Blast Trials

- Risk and Safety Management

- Accident and Expert Witness Investigations

- Gas Explosion and Hazard Risk Assessment by

- Gas Dispersion Through CFD Analysis

- Gas Explosion and Blast Wave Modelling

- Blast Loading FEA Structural Analysis

Consequence modelling is an integral part of technical risk management and fire safety engineering. Part of the design/analysis process requires integration of the output of consequence modelling into escalation modelling and estimation of structural damage, and impact on personnel.

Detailed knowledge of the scenario event in consideration for consequence analysis is important. Parameters affecting the consequence modelling and/or hazard imposed boundary conditions need to be assessed and verified in order to ensure that the model closely represents reality. AMOG personnel have considerable experience and expertise in such analysis. This includes the capability of modelling situations such as jet fire, pool fire, explosion, buoyant and heavy gas dispersion, fire and smoke spread, and toxic gas dispersion. AMOG has evaluated a wide range of software and has acquired a suite of software/in-house routines for consequence modelling. The consequence modelling tools used by experienced AMOG engineers are validated and satisfy industry standards. Base and case-by-case validations of the consequence modelling and results form part of AMOG Consulting’s Standard Quality System for Approved Software Tools.

AMOG has a Computational Fluid Dynamics (CFD) modelling capability utilising state-of-the-art software programs and access to powerful and advanced computing resources. We are committed to providing your organisation with high quality engineering solutions using the best available tools and technologies.